Drum Granulator

EMCC offers reliable machinery that meets high standards in design and material selection to ensure continuity in your production process.

DRUM GRANULATOR

With EMCC’s rich experience in the field of fertilizer production, the drum granulators we produce have good performance in terms of quality, efficiency and service life.

We offer a variety of configurations to meet your processing needs of organic fertilizer, inorganic fertilizer, and compound fertilizer.

The drum granulator’s cylinder is equipped with two rolling rings, each supported on two supporting wheels, and installed obliquely on the foundation. The transmission device, consisting of a small gear meshing with a large gear on the cylinder, is driven by an electric motor to rotate the cylinder.

WORKING PRINCIPLE

The working principle of the drum granulator is to tumble the materials in the rotating drum, usually in the presence of binders. The binder makes the fine particles sticky, allowing them to absorb more fine particles, forming clumps in a process called agglomeration. The tumbling action helps to round the agglomerates and form a homogeneous mixture.

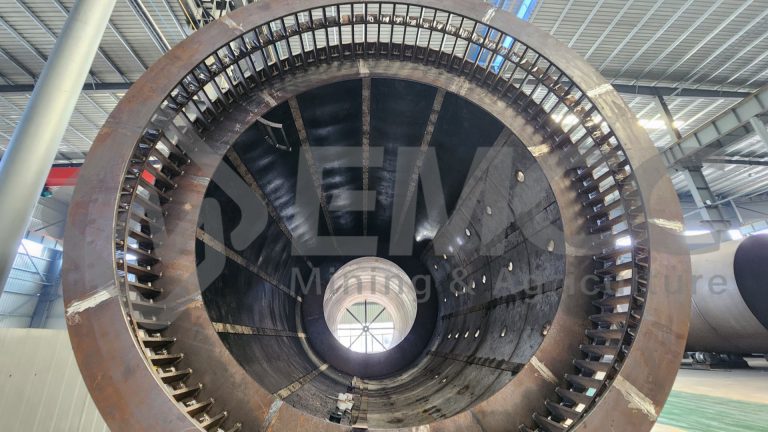

Generally, in order to prevent materials from sticking in the cylinder, several flexible rubber sheet linings are installed along the circumference of the cylinder inner wall, and are fixed each other to the cylinder wall by flat steel battens and bolts. Several breathing holes are set behind each flexible rubber plate and on the cylinder wall to ensure that when the cylinder rotates upward, each rubber plate will automatically sag and deform due to its own weight and the gravity of the sticky material, and the sticky material will crack and fall off, thereby removing the sticky material on the cylinder wall.

FEATURES

Diameter: 0.8– 4.5m (2.625′ – 14.763′ )

Capacity: 1 TPH – 200 TPH

Heavy duty design and structure.

Internal design maximizes efficiency

A variety of materials are available, stainless steel optional.

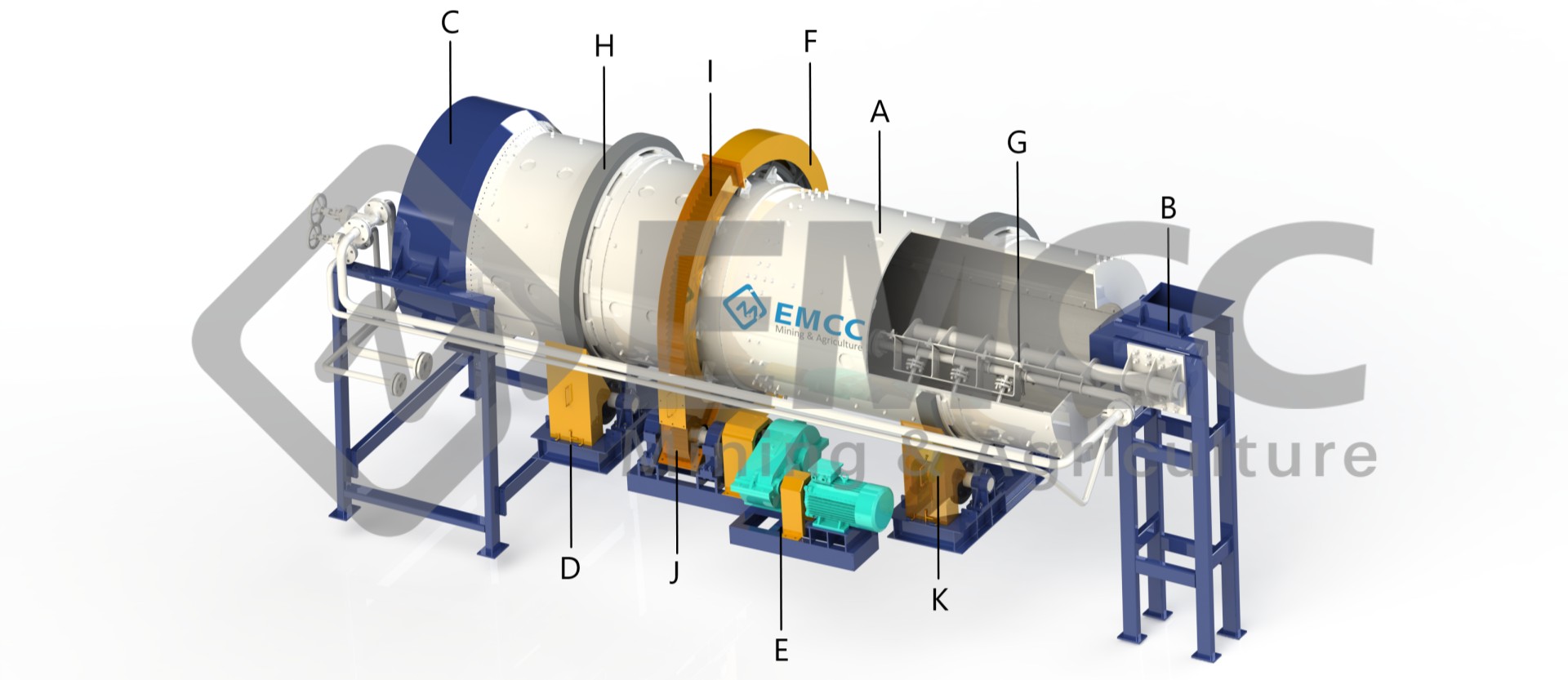

ROTARY DRUM GRANULATOR COMPONENTS

APPLICATIONS & MATERIALS

The rotary drum granulator is one of the most widely used machines in the field of granulation, especially if the output requirements are high, such as:

DAP (di-ammonium phosphate) and MAP (mono-ammonium phosphate)

NPK Grades

Ammonium Sulfate

TSP (triple super phosphate) and SSP (single super phosphate)

Organic fertilizer

Pipe Reactor Grades

PHOTOS

RESOURCES

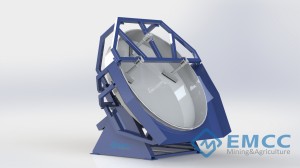

Best Practices for Maintaining a Disc Granulator

The disc granulator, also known as a pan granulator, is a

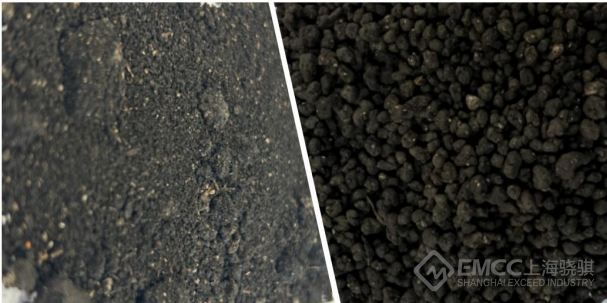

EMCC R&D LAB: CHICKEN LITTER TO ORGANIC FERTILIZER GRANULE

After batch agglomeration testing were conducted on small samples of