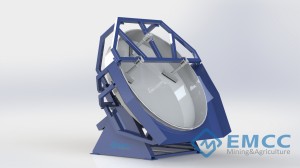

Disc Granulator is a kind of granulator, the granulation success rate can reach more than 93%. The application of this machine greatly reduces labor intensity and improves labor efficiency.

1. Specific installation points:

1) The equipment should be installed on a level concrete foundation and fixed with anchor bolts.

2) Pay attention to the verticality of the main body and the horizontal when installing.

3) After installation, check whether the bolts in each part are loose and whether the door of the main engine is fastened. If so, please fasten it.

4). Configure the power cord and control switch according to the power of the equipment.

5) After the inspection is completed, a no-load test run is carried out, and the test run is normal and production can be started.

2. Points to note when the equipment is put into production:

1). Check whether the reducer is filled with gear oil and whether the rotation direction of the disc is correct before starting the equipment.

2). After running and pressing the start button, the host starts, and observe whether the equipment is operating normally, whether there is vibration, and whether the rotation is stable.

3). Feeding and watering can be carried out after the filling and equipment of the granulator are operating normally.

4). After using granulation adjustment and filling, you can adjust the angle of the disc according to the requirements to make the granules reach the required size.