SOP Production Line

EMCC has been delivering custom process equipment, process development services, and service support to companies internationally for over 10 years.

SOP Production Line

Potassium sulfate is mainly used in tobacco, sugar beets, grapes, watermelons, potatoes, garlic, tea and other potassium-loving and chlorine-not loving crops. Potassium sulfate, as a fertilizer, can improve the quality of crops, such as the combustibility and color of tobacco, improving the sweetness and color of berries and melons more vivid etc., potassium sulfate is widely used in the production of nitrogen, phosphorus, potassium (N, P, K) ternary compound fertilizer.

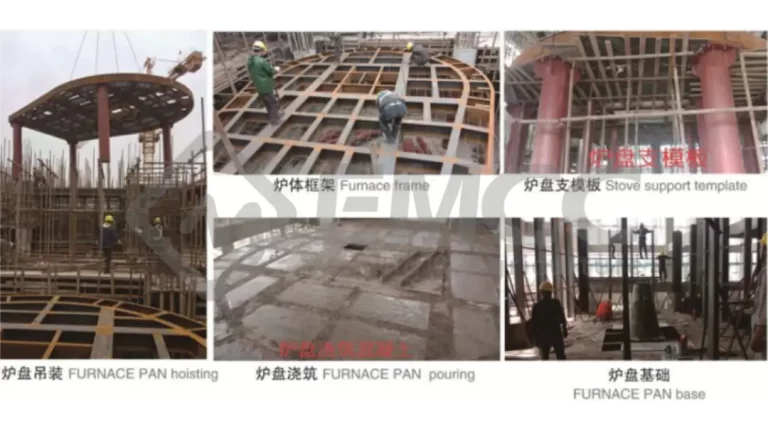

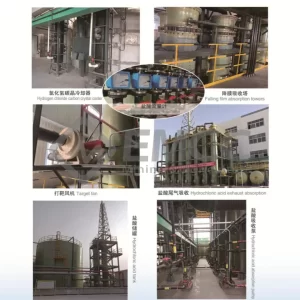

On the basis of the original German Mannheim potassium sulfate production process, through more than ten years of equipment manufacturing and production practice experience, we have fully studied its working principle to improve the structure and materials of the reactor, and successfully solved the problem of corrosion and high temperature resistance of the furnace internals. The hydrogen chloride absorption part uses new materials and new processes to improve the absorption rate, so that the material is evenly heated and completely reacted, the three wastes are discharged to the standard. The equipment maintenance cost is reduced by 60%, the energy consumption is reduced by 20%, and the unit yield is increased by about 20%, and the production enterprises benefit greatly.

The ADVANTAGES AND PROMISE OF THE NEW MANNHEIM FURNACE:

The new Mannheim reactor developed by our company adopts new refractory materials, improves the brick-type combination method, adopts double flue structure and uses special cement to improve the thermal conductivity of silicon carbide, which greatly reduces energy consumption and improves production capacity. It has the advantages of lower unit consumption of natural gas than similar production lines, lower exhaust gas discharge than the national standard, longer service life of furnace internals. longer overhaul cycle than similar products, and increased economic benefits. It is deeply trusted by customers.

Our company has a skilled and experienced professional team, with a number of technical personnel, and many years of skilled experience in equipment installation , kiln masonry, process guidance and production operation team to ensure that the production line from design, manufacturing, installation, commissioning and trial production smoothly and safely.

FEEDING SYSTEM

COOLING DELIVERY SYSTEM

REACTOR SYSTEM

HYDROGEN CHLORIDE ABSORPTION SYSTEM

CIRCULATING WATER SYSTEM

PACKAGING PROCESS

CONTROL SYSTEM

The use of DCS or PLC automatic control system can better monitor the running status of the equipment, and at the same time realize automatic proportional feeding and automatic temperature control, which greatly improves the stability of product quality and reduces the labor intensity of workers.

RESOURCES

Potash Critical In Plant Stress Tolerance

As a leader in potash fertilizer production equipment and systems, we

Mannheim potassium sulfate production line helps global agricultural development: technology and environmental protection are equally important

In recent years, the global demand for high-efficiency fertilizers has