INTRODUCTION

Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) is an engineering and equipment manufacturer. We are known as the material experts, able to solve all sorts of material processing and handling problems, and now serve nearly every industry, from energy and agriculture, to mining and minerals.

EMCC has become the premier name in providing feasibility testing, process and product design, and custom processing equipment for drying requirements. From idea, to complete process solutions and custom processing equipment, we offer Concurrent vs. Countercurrent Dryers.

CONCURRENT VS. COUNTERCURRENT DRYERS

There are two basic types of Direct Fired Dryers:

- Concurrent (or parallel flow)

- Countercurrent (or counter flow)

In both types of dryers, the material to be dried comes into direct contact with the hot process gases. These gases are generally provided as products of combustion from an oil, gas or solid fuel fired furnace in temperatures ranging from 250 to 1,000 degrees Celsius.

CONCURRENT ROTARY DRYERS

In a concurrent dryer, wet material and the hot process gas enter the dryer on the same end. Thus, dry material and the exhaust vapor exit the dryer on the same end. Concurrent dryers are the most commonly used and are used for drying materials that contain a high moisture content, are heat-sensitive, or tend to stick or cake.

There are two primary advantages to using a concurrent dryer:

- Since both the material and the gas enter the dryer in the same location, the wettest material comes into contact with the hottest gas. This helps the surface moisture to evaporate very quickly. This configuration also allows the dryer shell to operate at a somewhat cooler temperature than in countercurrent, which prolongs the life of the dryer and reduces the need for maintenance, keeping both the dryer and the material from being overheated.

- Because the dry material and vapor leave the dryer on the same end, there is a direct relationship between the temperature of the exhaust gas and the dried product’s condition. This enables the system to adequately respond to the exhaust gas temperature, allowing for immediate heat load adjustment to changes in conditions upstream of the dryer. The dried product comes into contact with the gas at its lowest temperature, which enables control of the moisture content, generally through keeping the exhaust gas temperature at a pre-set value.

Concurrent dryers are used for a variety of applications, depending on whether the heat transfer is by convection or by a combination of convection and radiation.

In cases where heat transfer is by convection, the wet material comes into contact with the hottest gases, which are supplied by an external source. This application is used for filter cakes, minerals, fertilizers, clays, coal/coke, phosphates, animal feeds, sludges and stillage.

In cases where heat transfer is by a combination of convection and radiation, the wet material comes into contact with the hottest gases, which are supplied by an internal burner, providing higher thermal efficiency. This application is best suited to heavy ores, sand, refractory materials, crushed rock and stone, slag and limestone/clay separation.

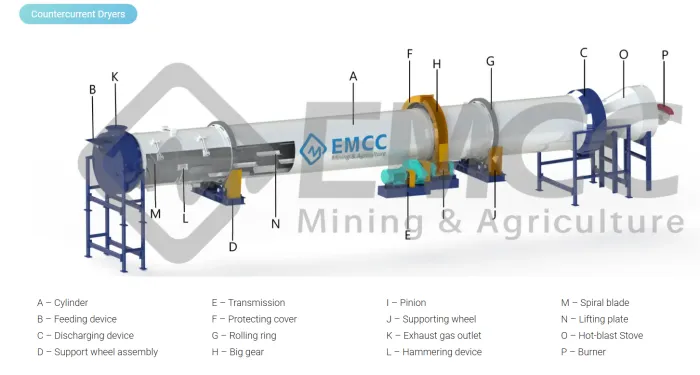

COUNTERCURRENT ROTARY DRYERS

In a countercurrent system, wet material is fed into the dryer on one end, and the hot process gas enters the dryer on the opposite end. Similarly, the dried material exits from the end of the dryer opposite the exhaust vapor.

Countercurrent dryers are well suited for materials that need to be dried to high temperature levels, in cases where the final traces of moisture are difficult to eliminate or where a higher product temperature is required. Countercurrent dryers are also useful as combined dryer/preheaters.

A countercurrent dryer is useful in two specific types of drying processes:

- The material that will be dried also needs to be heated. Some aggregate and ore processing jobs require that the material be heated as well as dried. In such applications, the wet material is fed into the cold end of the drum and moves toward the hot end. Because the exhaust vapor and the material exit the dryer at opposite ends, there is no correlation between the two temperatures.

- All materials have some level of internal moisture. Materials with a high percentage of internal moisture need ample time to permit the water to move to the particle’s surface for evaporation.

Countercurrent dryers are used for a variety of applications, depending on whether the heat transfer is by convection or by a combination of convection and radiation.

In cases where heat transfer is by convection, the dried product comes into contact with the hottest gases, which are supplied by an external source. This application is best suited for sugar, chemical salts, silica gel, ores and minerals, pigments and crystalline products.

In cases where heat transfer is by a combination of convection and radiation, the dried products comes into contact with the hottest gases, which are supplied by an internal burner. This application is used for gravel, limestone, crushed rock, sand, roadstone, slate, combined drying/preheating and calcining.