Be it for a fertilizer or soil amendment product, the granulation process (and the many configurations thereof) requires a delicate balance of variables in order to economically produce a product that meets the desired qualities.

Depending on the feedstock, the end product, and the process used, these factors can vary significantly. For this reason, testing is often an essential step in the development of a process for producing a granular soil amendment or fertilizer product.

However, there are a few overarching themes that play into the success of any granulation operation, no matter what the product. These are outlined here.

MEASURING GRANULATION SUCCESS

It’s important to recognize that the “success” of a granulation operation can mean many things. There are two primary ways in which a granulation process will need to be successful in order to make sense pursuing on a commercial scale:

END PRODUCT SPECS ARE ACHIEVABLE

Not all materials are capable of granulation. Similarly, some materials may agglomerate to an extent, but result in an inferior product. This is often the first explored avenue in assessing a granulation process: is the process/product physically possible?

ECONOMIC FEASIBILITY

Once the process has been deemed physically possible, the next question is whether or not the process required to produce the desired product is economically feasible. Just because a process can be carried out, does not mean that it is economically viable to do so.

Many factors that may not be obvious at first can throw off the economies of a granulation process. For example, perhaps in order for the process to work, an increased amount of one of the components is needed. The required increase means the product would be too costly to produce compared to its market value.

Or, perhaps a more costly binder is required to make the process work; or the most effective binder is not available in the project’s locale, requiring substantial transportation costs to get it there. Many potential factors exist. Similarly, if a significant amount of energy (natural gas, fuel oil, etc.) is required during the production process, costs may become too high.

KEY FACTORS INFLUENCING THE GRANULATION PROCESS

Whether or not the granulation process is physically possible is influenced by several parameters. The balance of these parameters, culminating in a product with the desired characteristics, is often determined through extensive testing in a facility such as the EMCC Innovation Center, or in an in-house pilot plant. The factors that have the most influence on whether or not the process is capable of being carried out are the characteristics of the feedstock, the desired end product characteristics, and the binder.

FEEDSTOCK MATERIAL CHARACTERISTICS

The starting point in any granulation operation is the material feedstock. Feedstock must meet several parameters in order for granulation to be possible, let alone effective. Important feedstock characteristics typically include:

Particle Size Distribution

The particle size distribution (PSD) of feedstock is a key contributor to the success of a granulation process. PSD should be generally uniform, with variation in desirable ranges differing depending on the unique project. In all cases, large particles will need to be removed or broken down, as they will inhibit granulation. This is commonly seen with manure feedstocks that may contain bedding fibers.

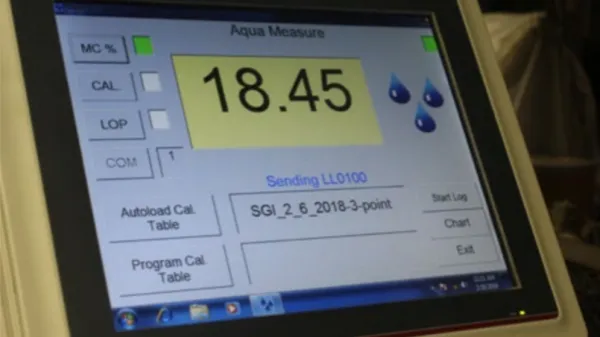

Moisture Content

The wet granulation process relies on capillary forces to be effective. This requires the addition of moisture throughout the granulation process, typically through the inclusion of a liquid binding agent (even in the form of water). As a result, the feedstock must be within a moisture range that can accept additional moisture without overwetting. This may necessitate a drying step prior to granulation, or back mixing—a technique in which dried material is mixed into the wet feedstock to reduce the overall moisture content of the inlet material.

Material Composition

The chemical and physical properties of each individual component in a product—and how they will interact—will need to be considered to avoid unintended consequences. For example, some components may chemically react to increase the bond strength between particles, resulting in a much higher crush strength than may be desired, ultimately causing delayed nutrient delivery. Similarly, components may be difficult to uniformly combine as a result of their physical or chemical properties. Some others may tend to become soft and/or plastic-like on wetting, requiring an adjustment in the process to work around this characteristic. Exothermic and endothermic reactions can also be problematic. The amount of preconditioning required to bring a material within the range of specifications can sometimes push CAPEX and OPEX past the point of economic feasibility.Furthermore, the desired components for a product may require that the ratio of these components be adjusted in order for granulation to be successful. These are only a few examples of how material composition can impact the physical and economic viability of a project.

DESIRED END PRODUCT CHARACTERISTICS

In addition to the material’s properties as a feedstock, the desired end product characteristics can also influence whether or not the granulation process can be successful, particularly in relation to particle size.

In some cases, it may be challenging to go beyond a certain pellet size, simply due to the material characteristics. The coarseness of particles, as well as their shape, can cause limitations in producing larger agglomerates.

Similarly, some materials can be difficult to produce as very small agglomerates due to yield concerns.

BINDER

The binder also contributes substantially to the overall success of a granulation operation. As a reminder, binder contributes to process success in three key ways:

Fostering particle growth (coalescence or accretion)

The binding agent is what allows seed pellets, or nuclei, to become tacky and pick up additional fines. Without a binding agent, particles would simply tumble in the granulation device, without growth.

Ensuring proper green strength

Achieving and maintaining an adequate green strength is what allows the pellet or granule to stay intact throughout processing. Various transfer and drop points often exist between the granulation device and the end product; particle integrity must be able to be maintained throughout this process to ensure that pellets don’t break down during processing.

Achieving desired crush strength

The binder also contributes to the crush strength of the end product, allowing it to withstand handling, transportation, storage, and application. Dry crush strength essentially ensures that a product arrives at its destination as intended and can be utilized exactly as designed, without prematurely breaking down.

Binders are available by the hundreds, each offering own unique properties in performance and composition. Depending on the material feedstock and the desired end product characteristics, some binders will be better than others. Furthermore, as mentioned, several economic considerations will need to be evaluated during the binder selection process.