Many factors are taken into consideration when designing a rotary drum dryer that can both efficiently and effectively dry a material. Factors such as the material’s bulk density, heat sensitivity, particle size, and flowability, among others, all interact to influence how the material will behave in the dryer, and subsequently, how the dryer should be designed to optimally work with those characteristics. One critical factor in designing a rotary dryer that produces the desired end product characteristics is the air flow configuration, or the direction in which the process gas flows through the dryer in relation to the material.

Many factors are taken into consideration when designing a rotary drum dryer that can both efficiently and effectively dry a material. Factors such as the material’s bulk density, heat sensitivity, particle size, and flowability, among others, all interact to influence how the material will behave in the dryer, and subsequently, how the dryer should be designed to optimally work with those characteristics. One critical factor in designing a rotary dryer that produces the desired end product characteristics is the air flow configuration, or the direction in which the process gas flows through the dryer in relation to the material.

Rotary dryers are available in two types of air-flow configurations: co-current and counter current. Both options have been developed through extensive research and development in order to maximize the thermal efficiency of the rotary drying process. The selection of which configuration will best suit the process is based on the material’s properties, as well as overall process requirements, making it important to understand how each air-flow configuration works in order to fully grasp which type will best suit the drying process at hand.

Below is an overview on the advantages and disadvantages of these two types of rotary drum dryer designs.

The Co-Current Rotary Dryer

Best for: Materials that are heat-sensitive, maintaining product quality (NOTE: 90% of all rotary dryers are co-current for these reasons)

Key Advantages: Greater control over solids temperature and avoidance of overheating

Disadvantages: Slightly less thermally efficient than counter-current air flow

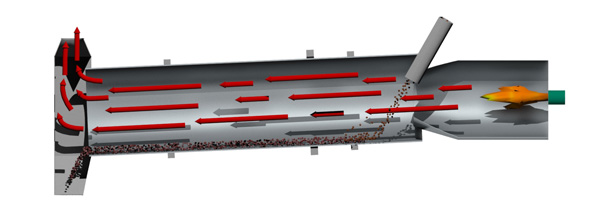

Co-current or parallel flow drying occurs when the drying air flows in the same direction as the material, or rather, when the material and process gas enter the dryer at the same end of the drum, as shown in the illustration below.

Co-curernt dryer(drier)

Advantages of the Co-Current Rotary Dryer

As mentioned, the majority of rotary drum dryers utilize the co-current air flow design. This configuration is chosen for several reasons:

Rapid Removal of Free Moisture

By introducing the solids and process gas in the same location, the process gas contacts the material in its wettest state, resulting in a quick initial reduction of surface moisture. Because of this fast initial drying, co-current dryers work best with materials that have high surface/free moisture such as glass. The lower surface moisture at the inlet of the drum also promotes improved flowability of the material through the drum, as the solids are less likely to stick as they tumble and cascade.

Ideal for Heat-Sensitive Materials

The co-current dryer is ideal for drying heat-sensitive materials. When a material is heat-sensitive, overheating can result in unwanted reactions, undesirable color changes in product, product degradation, or even a risk of fire. By utilizing a co-current configuration with heat-sensitive materials, it is much easier to prevent overheating, because the hottest gases are in contact with the wettest material and the temperature of the solids instead decreases as it moves through the dryer, preventing the potential for overheating.

Control Over Solids Temperature

Because the solids temperature correlates directly with the process gas temperature, the co-current design makes controlling the temperature of the dried material much easier. This is ideal for heat-sensitive materials that must be kept below a certain temperature threshold during the drying process.

Improved Dryer Longevity

The introduction of the material and process gas at the same location of the dryer causes a rapid initial cooling of the process gas, causing the dryer shell to run at a cooler surface temperature. This lower temperature reduces stress on the drum shell, promoting a longer life.

Disadvantages of the Co-Current Rotary Dryer

Higher Exhaust Gas Temperatures

The primary disadvantage of the co-current design is that it is slightly less thermally efficient, because the exhaust gas can never be cooler than the temperature of the solids, requiring more energy to be spent on keeping the exhaust temperature up. The need to ensure that the exhaust gas exceeds the temperature of the solids therefore results in wasted energy and slightly greater fuel consumption.

The Counter Current Rotary Dryer

Best for: Materials with bound moisture, or that require heating to a higher temperature

Key Advantage: More efficient

Disadvantages: Less control over solids temperature, greater potential for overheating

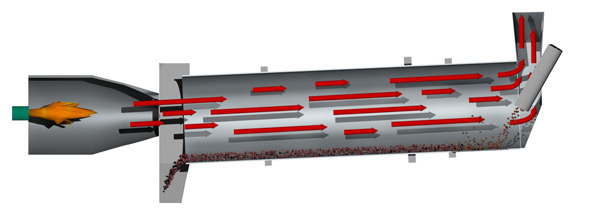

Counter-current drying occurs when the gas and material flow in opposing directions (i.e., the material is fed into one end of the drum, while the process gas is fed into the other end of the drum, as shown in the illustration below).

Counter current dryer(drier)

Advantages of the Counter-Current Rotary Dryer

The counter-current air flow design offers several advantages:

Gradual Removal of Moisture

Because the material comes in contact with the hottest process gas at its most dehydrated state, the counter-current configuration is ideal for materials with bound moisture. Bound moisture is typically not affected by the initial “flash-off” of free moisture, instead requiring more gradual heating to draw out moisture from within the material.

High Heat Capabilities

Similarly, materials that require high temperatures to release their moisture are also best served in a counter-current rotary dryer, since the solids are coming into contact with the hottest gases toward the end of the drying process.

Greater Thermal Efficiency (Lower Exhaust Gas Temperatures)

Counter-current dryers are often chosen for their efficiency, because more heat is spent on drying the solids than ensuring the exhaust gas temperature remains high. In other words, because counter-current dryers can tolerate gas temperatures lower than the solids, less fuel is required and excess energy is not wasted in the exhaust gas.

It’s important to note that the exhaust gas temperature must always be above the dew point. The potential for the exhaust gas temperature to reach the dew point is greater with a counter-current configuration and must be carefully managed; if the temperature were allowed to reach the dew point, condensation could occur in the ductwork and baghouse, clogging up the system. This is especially likely if the ductwork is not insulated.

Disadvantages of the Counter-Current Rotary Dryer

Less Control Over Solids Temperature

While a direct relationship exists between the material and process gas in the co-current design, the opposing flow of the solids and gas employed in the counter-current configuration makes it more difficult to control the temperature of the solids.

Risk of Overheating

Because the solids come into contact with the hottest gas in their driest state, the counter-current air flow also makes it easier to overheat the material.

If the inlet gas temperatures need to be lower to avoid overheating the material, additional fuel will be required, because more air which needs to be heated will be required, which can cut into the initial energy savings.

Other Considerations with Air Flow

While not directly related to the chosen configuration, there are a few other air flow considerations that should be kept in mind during the design process:

Whether or Not to Use a Combustion Chamber

Combustion chambers are often employed with direct rotary dryers in order to prevent contact between the burner flame and the material being processed. This is advantageous when working with heat-sensitive materials, or materials that might form undesirable compounds if exposed to the additional radiation of a flame.

Exhaust Gas Recycling

When using a combustion chamber, the secondary air can sometimes be provided via recycled exhaust gas from the dryer. Since this air is already preheated, a savings in fuel can be achieved if designed properly.

Conclusion

Understanding how each dryer configuration works is an important factor in designing the most efficient rotary dryer, and each configuration has its own unique advantages and disadvantages. EMCC encourages each material to undergo a research and development process at our on-site concept testing facility, the EMCC Innovation Center. The information gained through our proven testing procedures allows us to design the most efficient and beneficial drying system for our customers’ material needs. For more information on co-current or counter-current drying, contact us today!