Batching Systems

EMCC offers reliable machinery that meets high standards in design and material selection to ensure continuity in your production process.

BATCHING SYSTEM

The automatic batching system is mainly suitable for mixing, batching and feeding of 2-8 materials. It is suitable for sites with continuous batching requirements.

This batching system is automatic, that carries materials on a conveyor belt, can perform dynamic and continuous measurement during operation and can send and receive corresponding control signals.

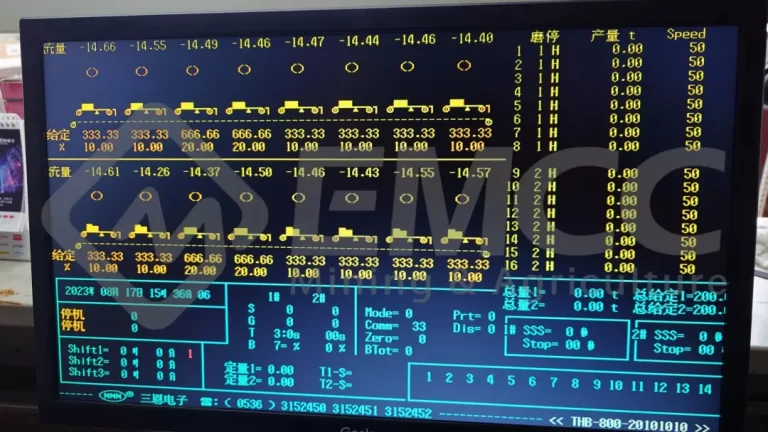

It is mainly composed of belt scale body, load sensor, speed sensor, frequency converter, motor, reducer, control instrument and other main components.

WORKING PRINCIPLE

The working principle is to use the load sensor and speed sensor installed on the scale body to measure the material quality and belt linear speed. The measured signals are processed by the computer, and a control signal is output to control the motor speed, changing the linear speed of the belt to make the actual flow rate close to the set value, to achieve the purpose of quantitative feeding.

The conveying volume and accuracy of the batching system are closely related to material characteristics, belt speed, etc. The material name, particle size (mm), bulk density (t/m3), flow rate (t/h), on-site temperature and other parameters should be known.

FEATURES

Suitable for many types of formulas, and normally 2-8 kinds of materials can be batched.

High batching accuracy and stable work performance.

The formula can be changed easily according to user production needs.

Small footprint (above ground, semi-underground, underground), low power consumption, simple operation and maintenance.

photos

RESOURCES

Food and Nutrition Security

About Fertilizers Fertilizers are used across the globe to support

CAC2025 has concluded successfully. Welcome to visit us!

The CAC2025 Agrochemical Exhibition was successfully held at the National Convention