INTRODUCTION

Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) is an engineering and equipment manufacturer. We are known as the material experts, able to solve all sorts of material processing and handling problems, and now serve nearly every industry, from energy and agriculture, to mining and minerals.

EMCC has become the premier name in providing feasibility testing, process and product design, and custom processing equipment for fertilizer blending and granulation. From idea, to complete process solutions and custom processing equipment, we offer unparalleled capabilities in fertilizer blending and granulation.

COMPLEX FERTILIZERS VS BLENDS

The area that has seen significant change is in the use of complex fertilizers over blends.

Fertilizer blends, in which primary components are separately manufactured and blended together to create a mixture that meets an overall nutrient grade, are still widely employed. However, instead of simply mixing these separate nutrient granules, many producers are moving toward manufacturing granules with the entire formulation in every pellet. This approach prevents issues associated with segregation of the nutrients, making results more predictable and effective.

While fertilizer blends have long been the industry standard simply because they were the only multi-nutrient option available, complex fertilizers have become the preferred choice in many cases—a fact exhibited in a recent forecast by Markets and Markets.

The growth can likely be attributed to the many advantages complex fertilizers can offer over blends, most notably when it comes to promoting uniform nutrient distribution on fields.

COMPLEX VS. BLEND: WHAT’S THE DIFFERENCE?

In some ways complex fertilizers and blends are similar; they both provide a multi-nutrient solution; both can incorporate additional micronutrients or other components into the formulation; and they can both be applied with standard spreaders.

Combined with their similarities, confusion around terminology often results in many perceiving no difference between these two fertilizer types. In actuality, however, they are very different. Here, we’ll use the following definitions:

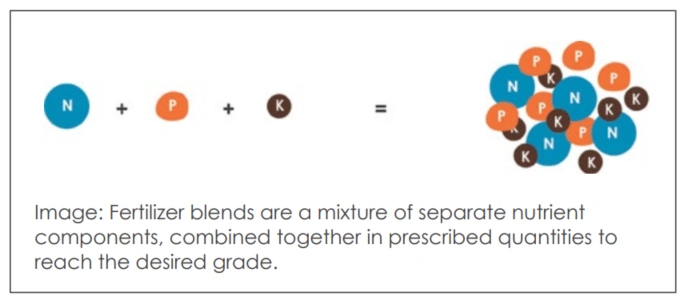

Fertilizer Blend – A multi-nutrient fertilizer that has been produced via bulk blending.

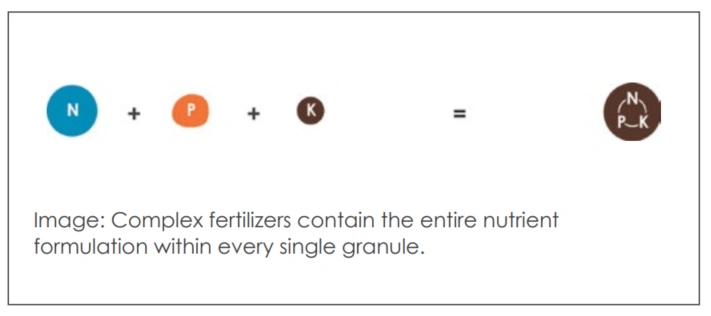

Complex Fertilizer – A multi-nutrient fertilizer where the entire formulation is singularly contained within each and every granule. May also be referred to as a Complex Compound Fertilizer, or CCF.

Compound Fertilizer – Any solid, multi-nutrient fertilizer. Can be a blend or a complex fertilizer.

FERTILIZER BLEND

A fertilizer blend is a multi-nutrient product in which the various components are separately manufactured and then “blended” or mixed together in specific quantities to create the desired formulation.

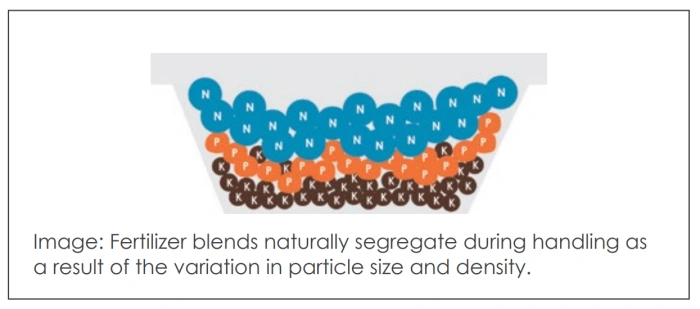

Because the various nutrient components are manufactured separately, they often vary in particle size and density.

COMPLEX FERTILIZER

Conversely, complex fertilizers are manufactured so that each and every granule contains the desired formulation instead of the nutrients being brought together as separate components. Raw materials are combined and homogeneous granules are produced —each containing the entire nutrient formulation, as illustrated above.

ACHIEVING UNIFORM NUTRIENT DISTRIBUTION

Uniform nutrient delivery is a key aspect not only in providing optimal crop nutrition and maximizing yields, but also in realizing the full value of the applied nutrients, and protecting the environment. When nutrients are unintentionally applied in excess, or in concentrated areas throughout a field, the potential for nutrient runoff to occur can be increased, though it’s important to note that this is dependent on many variables.

In order to maximize the ROI of applied fertilizers, provide complete nutrition, and reduce the potential for runoff to occur, it is necessary to achieve as much uniformity in nutrient delivery as possible.

While it might seem a slight difference, the all-in-one granule approach of complex fertilizers can make a big difference in performance when it comes to the uniform dispersion of nutrients on fields.

There are many factors that can influence the uniformity in which nutrients are distributed. Two primary considerations that can be controlled through the fertilizer itself are segregation of particles and the dispersal of particles from the spreader—both of which are significantly affected by product uniformity.

PARTICLE SEGREGATION

Particle segregation occurs as a result of the differences in size and density of the varying nutrient granules in a fertilizer blend. When exposed to the natural jostling of handling throughout the fertilizer lifecycle, this difference in particles results in larger particles being pushed upward—a phenomenon often referred to as the brazilian nut effect—in reference to a can of mixed nuts where brazil nuts make their way to the top of the tin as a result of handling.

When applied to granular fertilizer blends, this effect can cause nutrients to become concentrated to some

areas, instead of homogeneously mixed as they once were. This can occur during shipping or storage, or even in the spreader feed hopper. And while not the only factor influencing the uniformity of spreading, it has the potential to significantly affect the distribution of nutrients. As such, product uniformity is the key to the success of complex fertilizers; because all granules were manufactured in the same setting, the granules are much more uniform in size, shape, and density, eliminating the opportunity for segregation.

NUTRIENT DISPERSION IN SPREADING

The difference in particle size, shape, and density can also be problematic during spreading. Depending on the characteristics of the granules, they may be more or less able to fly long distances when expelled from the spreader, resulting in uneven dispersion.