When it comes to agglomerating material fines, compaction granulation and pelletization are often both investigated. Both methods are an effective solution, but each has distinct advantages and disadvantages. And while operating and capital costs are often the deciding factor between the two, there are many things to consider when choosing which method best suits your material and processing needs. Additionally, some materials may respond well to only one of these methods, making the choice clear. Other materials, however, will respond well to both (such as bentonite, coal, humate, potash, urea, and others) and will require further consideration.

ADVANTAGES TO PELLETIZING

FASTER NUTRIENT DELIVERY

Because pellets are not created through pressure, they are less dense than their compaction granule counterparts. The less dense pellets created in pelletizing can withstand handling, but can still quickly break down upon application, an ideal characteristic for soil amendments, fertilizers, and other applications that benefit from fast material breakdown.

LESS DUST AND FINES

Compared to compaction granules, pellets produce less fines; since pellets are round, there are no edges to break off and create dust.

BINDERS CAN SERVE AS BENEFICIAL ADDITIVES

Pelletization offers the opportunity to control formulation through the addition of specially-formulated binders, in order to create optimum pellet characteristics.

LOWER CAPITAL COSTS

The pelletizing method often requires a lower capital investment than compaction granulation.

A PREMIUM PRODUCT IS PRODUCED

The round, smooth pellets produced in the pelletizing process are considered a premium product.

Additionally, the pelletizing process offers the opportunity to include additives to further customize and enhance the end product.

DISADVANTAGES TO PELLETIZING

HIGHER PROCESSING COSTS

The use of a binder, and the required drying step results in higher processing costs when compared to compaction granulation.

ADVANTAGES TO COMPACTION GRANULATION:

LOWER PROCESSING COSTS

Processing costs are usually lower compared to pelletizing, because a binder and drying step are not typically needed.

DISADVANTAGES TO COMPACTION GRANULATION

ATTRITION

Attrition is the breakdown of granule edges into material fines and dust. This is common with compaction granules because of the rough, jagged edges. As mentioned, however, there are methods to aid in reducing attrition, but they can increase production costs.

Sometimes, it’s also sufficient to simply condition or micro pelletize material in a pin mixer or pugmill mixer, instead of pelletizing or granulating it. This is common for applications where the material only needs to be de-dusted, such as in cases where transportation to landfill is made difficult because of a dusty product.

Oftentimes, it is not clear which method of agglomeration will produce the desired results, and in these cases, testing may be required.

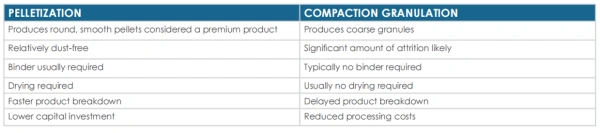

TABLE: HOW PELLETIZING AND COMPACTION COMPARE

The chart below provides a summary of the differences between pelletizing and compaction granulation.