Steel Belt Granulator

EMCC has been delivering custom process equipment, process development services, and service support to companies internationally for over 10 years.

Working principle

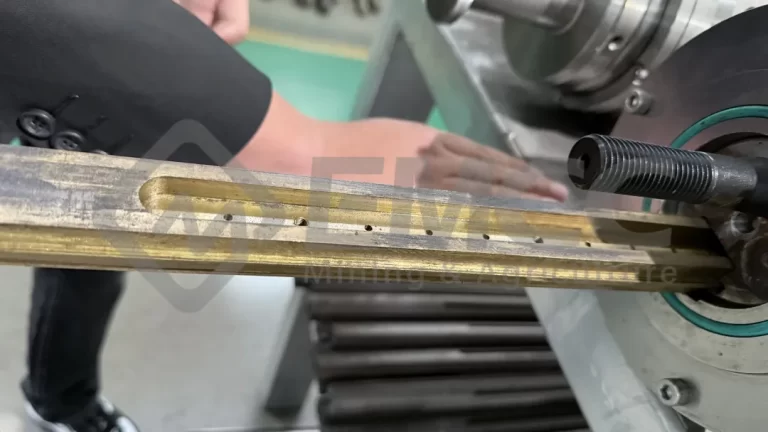

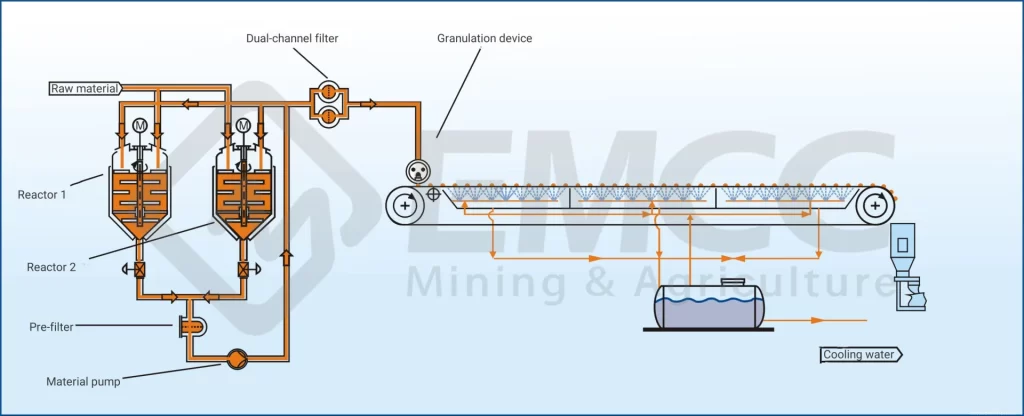

The molten material is feed into the granulator head at a constant speed through the material pump, and the granulated material is evenly dripped onto the steel belt surface running below it through the perforated outer drum. As the steel belt moves into the cooling area, the back of the steel belt is continuously sprayed with cooling water, the good heat transfer of the steel belt forces the material above the steel belt to be quickly cooled and solidified during the movement process, thereby achieving the purpose of granulation. The speed of the steel belt and the granulator head can be adjusted to obtain the most ideal particles.

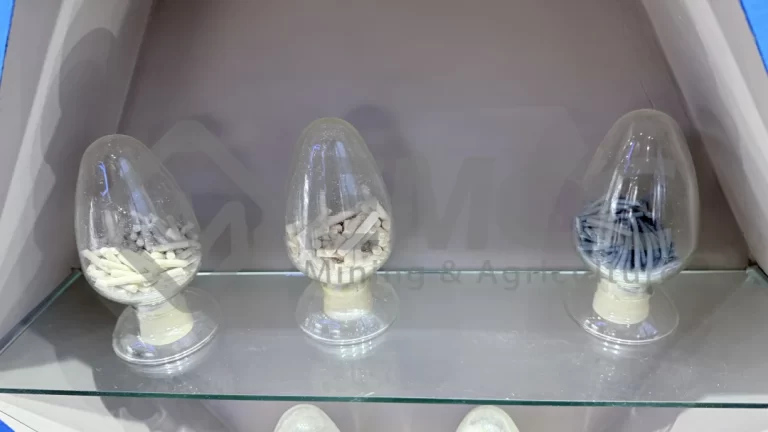

JT3000 granulator is suitable for various materials with a melting point (softening point) within 230℃. Typical application materials include: sulfur, resins, asphalt, maleic anhydride, partial anhydride, paraffin, stearic acid products, hot melts, organic intermediates, compound fertilizers, rubber and plastics and other additives.

Main advantages

Rapid solidification reduces the contact time with air and improves the production environment.

The product particles are uniform and dust-free, which is conducive to terminal metering.

Reasonable and compact structure, easy maintenance, can operate continuously and improve production efficiency.

photos

RESOURCES

The Incredible Impact of Granulation Binder for Fertilizer

In the world of agriculture, the quest for efficient and