Organic Fertilizer

China leading manufacturer of organic fertilizer granulation production line, EMCC design flexible granulator machines for fertilizer plants with low price and cost to make Chicken Manure|Cow Dung to fertilizer pellet.

ORGANIC FERTILIZER

Organic fertilizer is a type of fertilizer derived from plants or animals, primarily used to provide plant nutrition while improving the physical, chemical, and biological properties of the soil. Organic fertilizers are typically produced through the fermentation and decomposition of plant and animal residues, such as livestock manure, crop straw, and kitchen waste. There are various types of organic fertilizers, including farmyard manure(chicken manure/cow dung/pig waste), green manure, compost, humus fertilizer, and bio-organic fertilizer.

FEATURES

Comprehensive nutrients: Organic fertilizers contain a variety of trace elements and essential nutrients.

Slow-release of nutrients: Nutrients in organic fertilizers are released slowly, providing long-term absorption for plants.

Soil improvement: Organic matter enhances the water and nutrient retention capacity of the soil, improves soil structure, and increases soil aeration and moisture-holding capacity.

Increase biodiversity: Organic fertilizers increase the microbial diversity and population in the soil, which helps suppress diseases.

Reduce the use of chemical fertilizers: Organic fertilizers contribute to sustainable environmental practices.

THE PRODUCTION PROCESS OF ORGANIC FERTILIZERS GENERALLY INVOLVES THE FOLLOWING STEPS:

Raw material collection: Collect suitable raw materials (e.g chicken manure/cow dung/pig waste) for organic fertilizer production, such as plant and animal residues, agricultural waste, and household kitchen waste. These materials are rich in organic matter and serve as good sources for organic fertilizer production.

Pre-treatment: Raw materials are crushed, mixed, and moisture-adjusted to create a physical state and environment suitable for microbial growth and reproduction. Microorganisms may also be added to facilitate the decomposition and conversion of organic matter.

Fermentation: Pre-treated materials are stacked and undergo aerobic or anaerobic fermentation. Under appropriate temperature, humidity, and pH conditions, microorganisms decompose organic matter, generate heat, release CO2, NH3, and convert them into abundant nutrients. During the fermentation process, a compost turner machine is often used.

Maturation: After fermentation, the materials go through a maturation period to eliminate harmful substances and increase the stability of the fertilizer, making it more suitable for plant uptake.

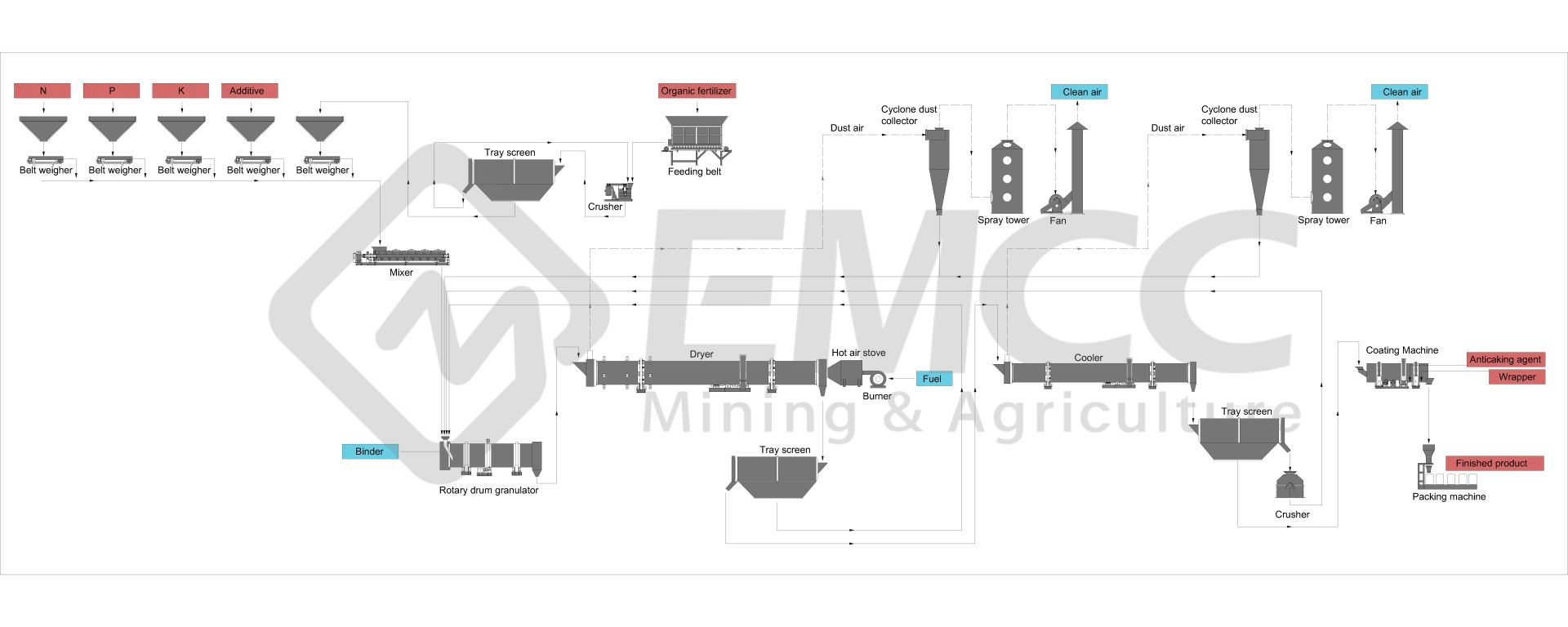

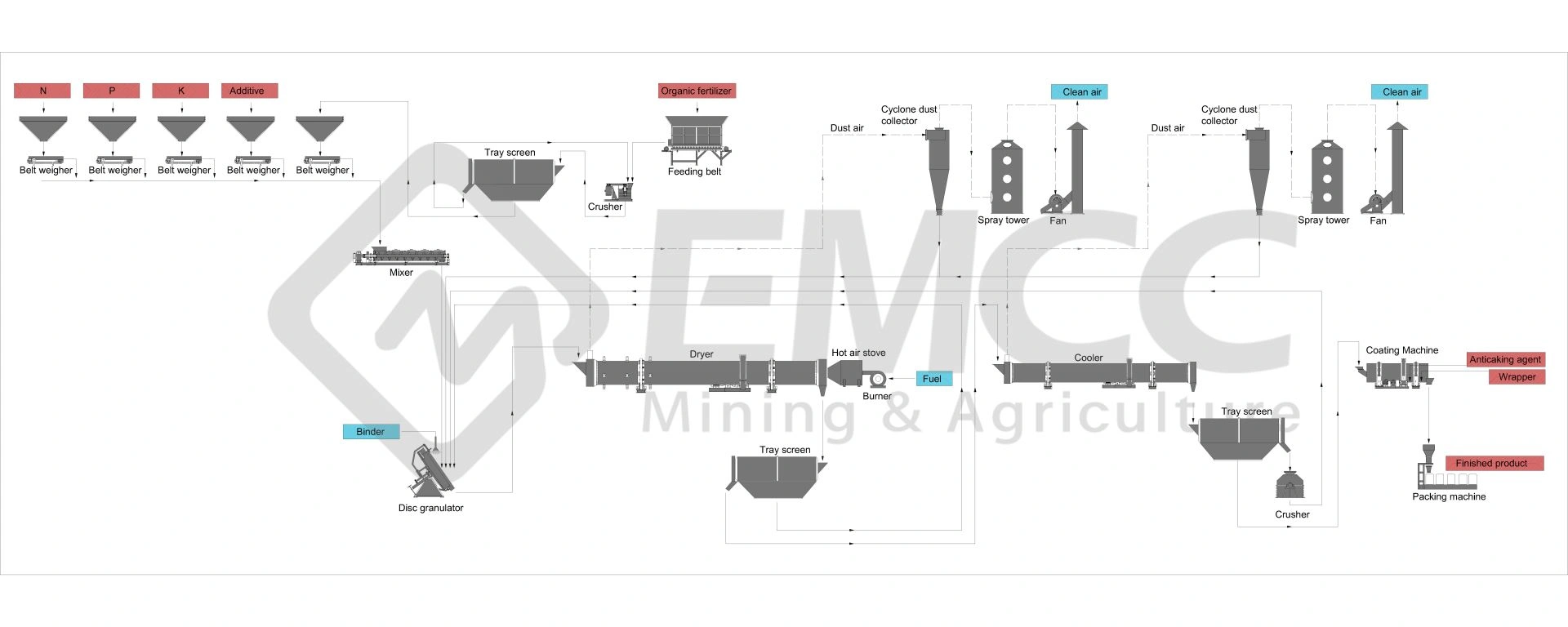

Screening and granulation: Matured materials are screened to remove large particles and incompletely decomposed substances. Then, the materials are granulated to form uniform particles for easy application and transportation. Disc granulation and rotary drum granulation lines are commonly used.

Drying and cooling: The granulated organic fertilizer is dried and cooled to reduce its moisture content and improve storage stability.

Coating: Qualified granular finished products add conditioning agents, etc. or change the colour.

Packaging and storage: Finally, the cooled organic fertilizer is packaged and stored, ready for transportation and sale.

The above steps outline the general process of organic fertilizer production, but certain adjustments and optimizations may be made based on specific circumstances and requirements. EMCC’s design team can provide you with a satisfactory solution.

WHEN USING ORGANIC FERTILIZERS, IT IS IMPORTANT TO CONSIDER THE FOLLOWING POINTS:

Decomposition degree: Insufficiently decomposed organic fertilizers may contain pathogens and weed seeds that are detrimental to plant growth. Therefore, it is essential to ensure that organic fertilizers have undergone sufficient fermentation and decomposition before use.

Nutrient composition: Different types of organic fertilizers have varying nutrient compositions and ratios. Choose organic fertilizers that are suitable for the specific nutrient requirements of the crops and soil conditions.

Application rate and timing: Determine the appropriate application rate and timing to meet the growth needs of the crops, avoiding over-application that can lead to nutrient imbalances or environmental pollution.

RESOURCES

Organic Fertilizers & Organic Production

The question “What is an organic fertilizer?” seems straightforward to

Warning | Uncomposted livestock manure is not organic fertilizer! It is garbage!

Only decomposed livestock manure can be called organic fertilizer. Undecomposed