Slow and controlled release fertilizer

EMCC has been delivering custom process equipment, process development services, and service support to companies internationally for over 10 years.

SLOW AND CONTROLLED-RELEASE FERTILIZER

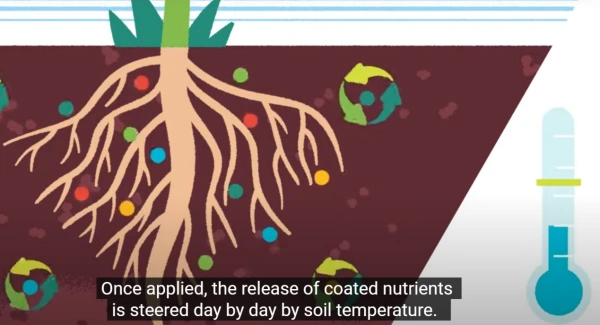

Slow and Controlled-release fertilizer is a new type of fertilizer that controls the release of nutrient elements through physical or chemical means to meet the nutritional needs of plants and minimize nutrient loss as much as possible. The main advantage of controlled-release fertilizer is that it can improve the utilization rate of fertilizer, reduce the number of fertilizer applications, save labor, and reduce the impact on the environment.

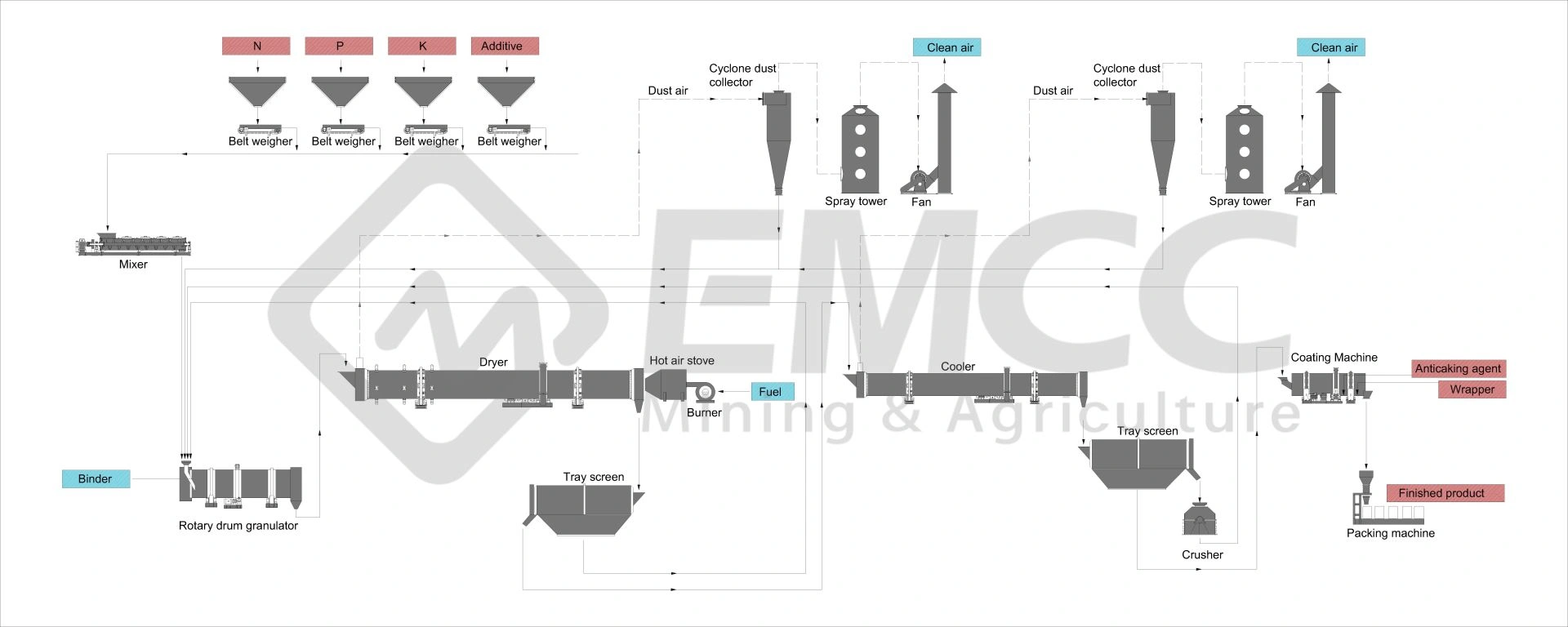

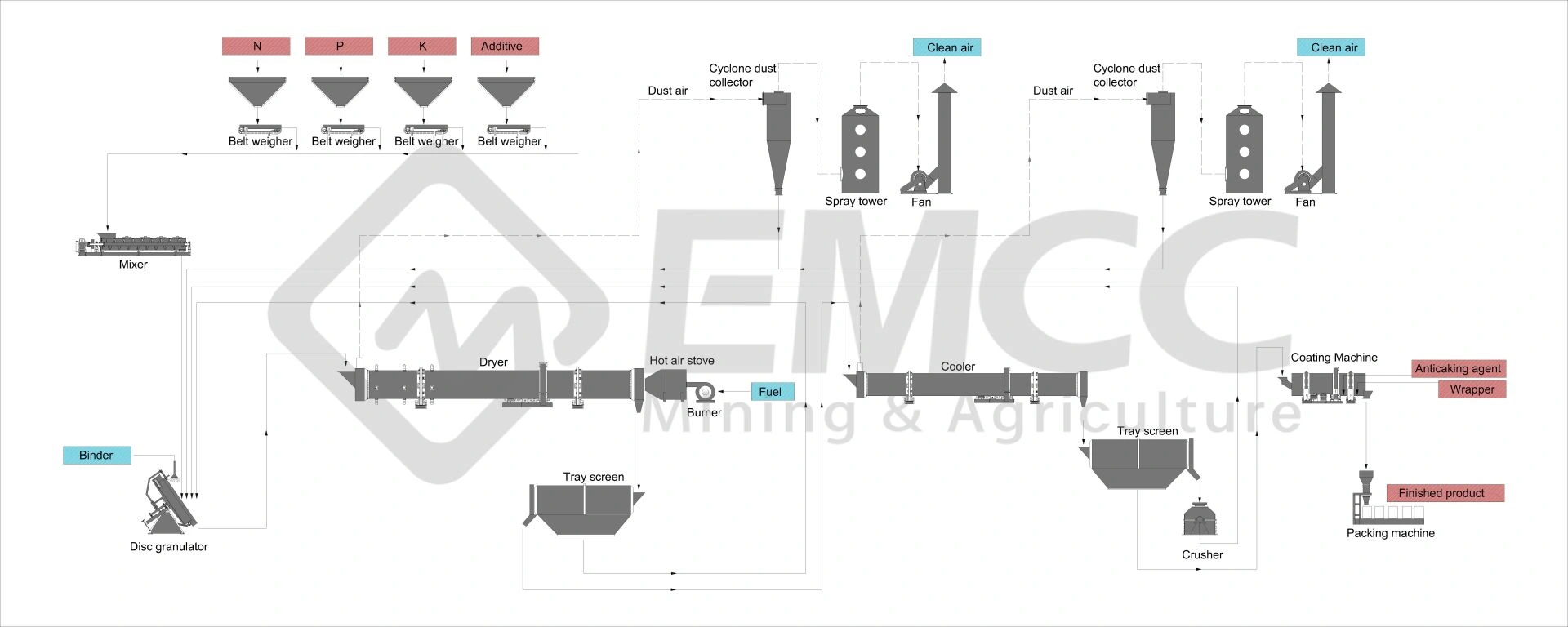

THE PRODUCTION PROCESS OF CONTROLLED-RELEASE FERTILIZER GENERALLY INCLUDES THE FOLLOWING STEPS:

Selection of raw materials: Choose inorganic or organic fertilizers that contain necessary nutrients (such as nitrogen, phosphorus, potassium, etc.) as raw materials.

Ingredient matching: First, different nitrogen, phosphorus, and potassium raw materials and other required raw materials are proportioned at the ingredient station according to the formula requirements.

Mixing: The proportioned nitrogen, phosphorus, and potassium fertilizers, as well as possible fillers and additives, are mixed together to form a fertilizer mixture.

Granulation: The mixture enters the granulator with added water, and granules are formed through physical extrusion or agglomeration. Commonly used granulation equipment includes rotary drum granulators and disc granulators.

Drying: Wet granules are dried by a dryer to remove excess moisture.

Cooling: The dried granules need to be cooled to reduce the temperature and prevent granule adhesion caused by high temperatures.

Screening: After cooling, the granules are screened to separate qualified granules from unqualified powder or large granules.

Coating: Qualified granular finished products are added with conditioners or their colors are changed.

Packaging: The qualified granules are packaged for sale or use.

When applying controlled-release fertilizer, the appropriate application rate and timing can be selected according to the crop’s needs and soil conditions to achieve the best fertilizer effect. By using controlled-release fertilizer, the necessary nutrients for crops can be provided more effectively, crop yield and quality can be improved, and the impact on the environment can be reduced.

RESOURCES

Controlled Release Fertilizers?

Controlled Release Fertilizers (CRFs) are specialized fertilizers coated with a