News

EMCC has been delivering custom process equipment, process development services, and service support to companies internationally for over 10 years.

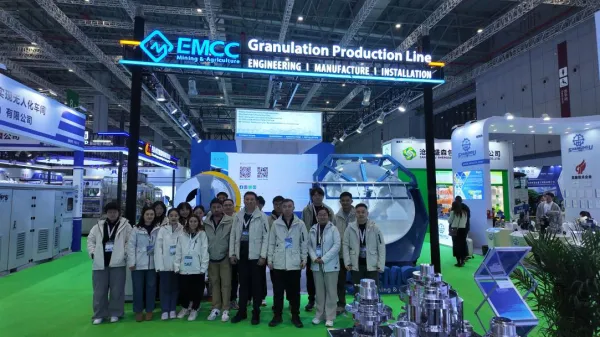

CAC2025 has concluded successfully. Welcome to visit us!

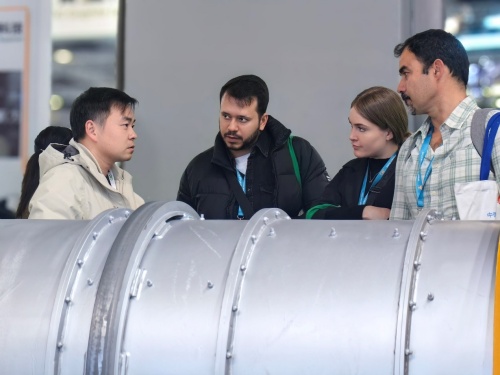

The CAC2025 Agrochemical Exhibition was successfully held at the National Convention and Exhibition Center (Shanghai) from March 17th to March 19th , 2025. EMCC (Shanghai Exceed Industry Co., Ltd.) successfully organized and participated in CAC2025 exhibition. In just three days of the exhibition, hundreds of customers and friends came to EMCC booth to visit, communicate, and consult. We would like to thank all new and old customers and friends for coming, and we would also like to thank every customer for your trust and support. After the exhibition, a large number of customers visited us. They visited our equipment production site and spoke highly of our large-scale factory, advanced production technology, sophisticated processing equipment, and high-quality equipment materials.

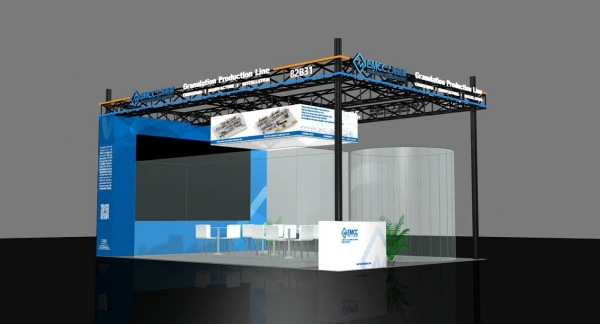

CAC 2025 Is Coming! Welcome your visit!

China International Agrochemical & Crop Protection Exhibition, referred to as CAC Agrichemical Exhibition. The 25th CAC ( CAC 2025 ) Agrochemical Exhibition will be held at the National Convention and Exhibition Center (Shanghai) from March 17th to March 19th. INVITATION Shanghai Exceed Industry Co., Ltd. will participate in the 25th China international Agrochemical & Crop Protection Exhibition from March 17th to March 19th, 2025 (the world’s largest and most professional one-stop procurement and exchange platform for agricultural machinery and equipment, pesticides, fertilizers, seeds, irrigation, greenhouses, and smart agricultural machinery). We sincerely invite you to visit Shanghai for the exhibition. Exhibition Hall – Booth Number: 8.2-82B31 Mr.Wang Tel: 021-58818577 Fax: 021-58817729

2024 CAC Vietnam Thank You All For Visiting!

In order to promote the capacity cooperation, product trade and technical exchange of Sino-Vietnam agrochemical industry, the “2024 Vietnam Agrochemical & Crop Protection Exhibition (CAC Vietnam)” is held in Ho Chi Minh City, Vietnam from 27th to 29th, November. CAC Vietnam aims to create a professional and trade exchange platform with large scale, wide influence and strong internationality based in Vietnam and radiating to the ASEAN region. EMCC (Shanghai Exceed Industry Co., Ltd.) successfully organize and participate in 2024 CAC Vietnam exhibition. In just three days of the exhibition, hundreds of customers and friends came to EMCC booth to visit, communicate, and consult. We would like to thank all new

EMCC and SRICI have deep cooperation

Recently, Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) and Shanghai Research Institute of Chemical Industry (hereinafter referred to as “SRICI”) officially announced a strategic cooperation to jointly develop fertilizer production technology and equipment, aiming to improve the fertilizer quality and performance, while exploring innovative technologies for fertilizer production. With the rapid development of the fertilizer industry, consumers have increasingly higher requirements for fertilizer quality and appearance, and high-performance fertilizer production technology has become an indispensable part of fertilizer production. In this cooperation, EMCC and SRICI will jointly develop fertilizer production technology and equipment, representing the latest development trend of the fertilizer industry. This cooperation is an

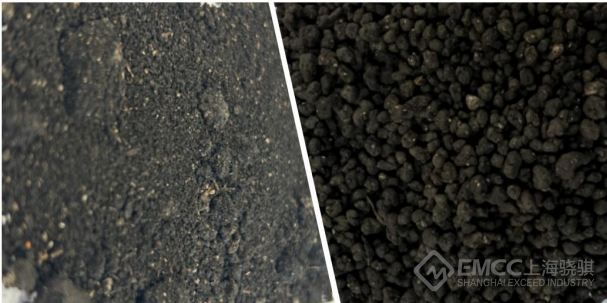

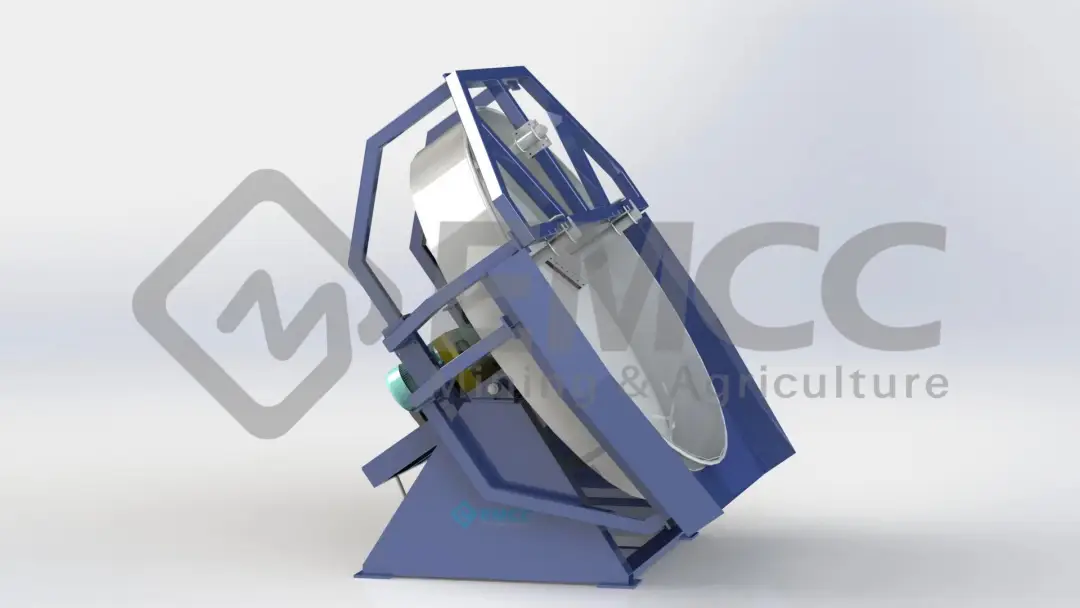

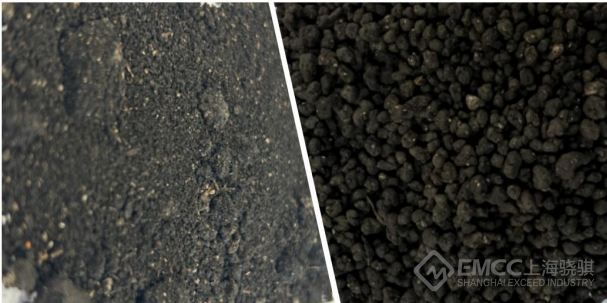

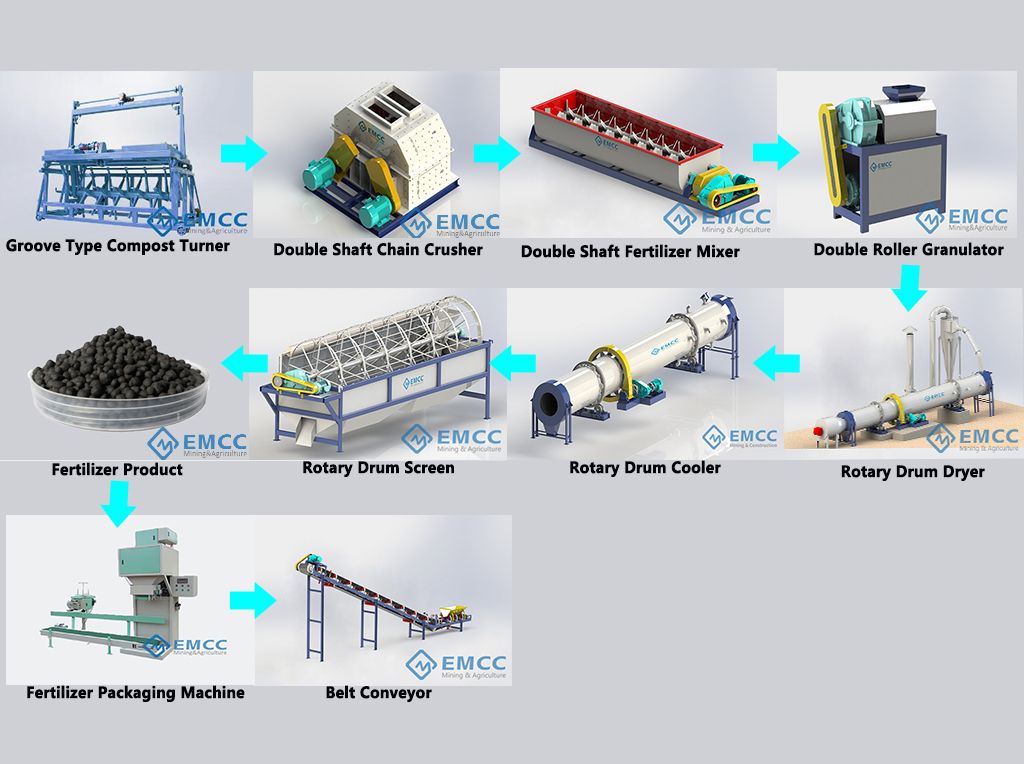

EMCC R&D LAB: CHICKEN LITTER TO ORGANIC FERTILIZER GRANULE

After batch agglomeration testing were conducted on small samples of the material to determine initial feasibility, continuous testing was carried out successfully by the EMCC R&D team. The spherical pellet produced by our granulation technique and equipment was exactly what the customer was looking for. As one kind of dust free pellet, it’s capable of being blended with other fertilizers to create improved blends. With the granulation technique and equipment from EMCC Industry,this turnkey fertilizer granulation plant project will allow our customer to produce the desired fertilizer granule on their own.

2024 CAC HAS CONCLUDED SUCCESSFULLY. THANK YOU ALL FOR VISITING!

China International Agrochemical & Crop Protection Exhibition, referred to as CAC Agrichemical Exhibition. The 2024 CAC Agrochemical Exhibition was successfully held at the National Convention and Exhibition Center (Shanghai) from March 13th to March 15th. As one of the most influential exhibitions in the global agrochemical industry, EMCC (Shanghai Exceed Industry Co., Ltd.) successfully organized and participated in 2024 CAC exhibition. In just three days of the exhibition, hundreds of customers and friends came to EMCC booth to visit, communicate, and consult. We would like to thank all new and old customers and friends for coming, and we would also like to thank every customer for your trust and support. We

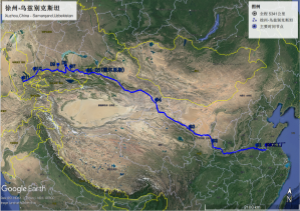

Direct to Central Asia! EMCC products, transport in one step

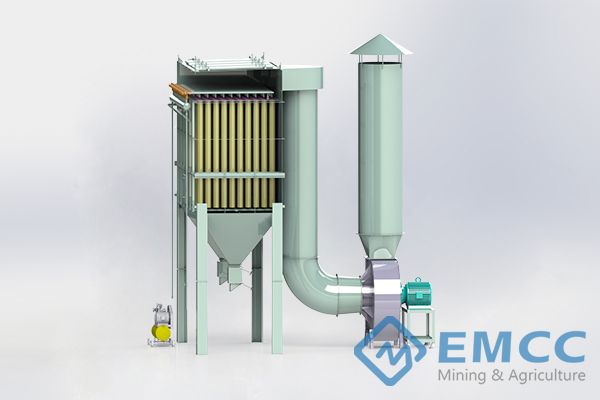

Recently, an Uzbekistan customer has been purchasing from EMCC production line equipment for two years, which is mainly for dust collect and agitate, will be shipped on January 19, 2024.1.19. As continuously discussed regarding product design between the customer and EMCC’s senior technical staff, the goal of optimizing the product’s appearance, and performance obtained consistent customer satisfaction. Product production Adjust the coaxiality, improve the axis bending. Effective working life is longer, operation and maintenance costs are reduced. Considering the geographic location, EMCC combines data analysis and artificial intelligence in product transportation to optimize cargo delivery routes and cut down on transit time. Transport route The products were shipped 5,341 kilometers by train from the EMCC’s facility in

Uzbekistan Project Successfully Delivered

Recently, Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) completed a batch of important delivery tasks and provided high-quality products and services to Uzbekistan project customers. This project are large-scale equipment with a diameter up to 4500mm. We EMCC, successfully completed this project with our professional equipment designing, manufacturing and comprehensive service capabilities. EMCC will continue to uphold its original aspirations, constantly improve its technical strength, and give back to new and old customers with better products and sincere services!

EMCC CAN PROVIDE YOU WITH CUSTOMIZED SERVICE OF DRUM DRYER

The organic fertilizer dryer is mainly used to dry granular materials within a certain humidity range. It is suitable for areas with relatively developed large, medium and small aquaculture. Depending on the requirements of the dried product, different heat sources can be used. Such as: gas generator, direct heating hot blast stove, indirect hot blast stove, heat transfer oil, electric heating, steam, etc. This machine is suitable for chicken manure, cow manure, duck manure and livestock manure with moisture content below 65%. It has a good effect on developing feed resources, reducing feeding costs and reducing environmental pollution. We have a solid reputation for the best rotary dryers in the

EMCC WILL BE YOUR MOST RELIABLE PARTNER

Our company has long been committed to providing high-quality and comprehensive support services to ensure the stable operation of customer equipment. Our company has a group of senior debugging personnel with rich experience, who can solve all kinds of failures of various equipment very well. Strong user support is one of our major advantages. The long-term development of the company is inseparable from the support of customers. In order to further safeguard the interests of customers, improve customer satisfaction, and give back to new and old customers, we make the following commitments to new and old customers, and welcome new and old customers to supervise us and give valuable opinions.

EMCC CAN PROVIDE A VARIETY OF EQUIPMENT TO MEET CUSTOMERS’ GRANULATION NEEDS

EMCC provides lots of solutions to meet your granulation requirements, from Project Design, Granulation Equipment Manufacturing, and Granulation Line Installation. Whether you are looking forward to produce organic or inorganic fertilizers, reduce dust problems, convert waste materials to commodities, or improve product characteristics, we will help you to create efficient granulation production lines and achieve your commercial goal.

Food and Nutrition Security

About Fertilizers Fertilizers are used across the globe to support sustainable agricultural production, and it is estimated that half the food we eat is produced thanks to mineral fertilizers. Food and nutrition security exists when all people, at all times, have physical, social and economic access to sufficient, safe and nutritious food. The Food and Agricultural Organization of the United Nations (FAO) estimates that around 9.9% of the world population (768 million people) were undernourished in 2020. At the same time, micronutrient deficiencies affect an estimated 2 billion people globally. Producing enough food, feed, fiber and bioenergy for a world population of almost 10 billion people by 2050 requires an

The Incredible Impact of Granulation Binder for Fertilizer

In the world of agriculture, the quest for efficient and sustainable farming practices has always been at the forefront. Fertilizers, as an integral part of modern agriculture, have undergone significant advancements over the years, and one such innovation is the use of granulation binders. This remarkable development has transformed the way we approach fertilization, making it not only more efficient but also more environmentally friendly. Granulation binders, also known as binding agents, are essential for turning loose fertilizers into granules. The advantages of granules include improved handling, controlled nutrient release, uniformity, reduced runoff, customization, and long-term soil health. These benefits enhance crop yields and promote sustainable farming practices. Enhanced Nutrient

What Is Humic Acid?

Humic and Fulvic acids are the final break-down constituents of the natural decay of plant and animal materials. These organic acids are found in pre-historic deposits. Humic matter is formed through the chemical and biological humification of plant and animal matter and through the biological activities of micro-organisms. Humic acids are complex molecules that exist naturally in soils, peats, oceans and fresh waters. The one source of humic acids are the sedimentation layers referred to as Leonardite. These layers were originally deep in the earth’s crust, but over many years have been exhumed to near-surface location. Humic acids are found in high concentration in these layers. Leonardite is organic matter,

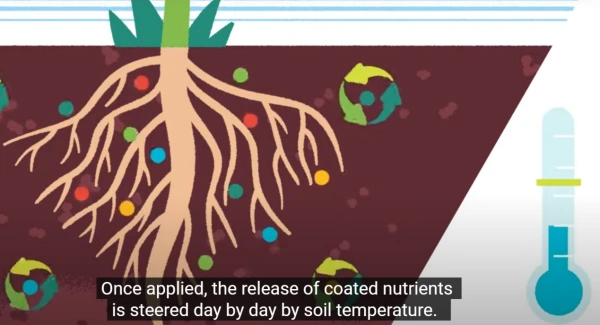

Controlled Release Fertilizers?

Controlled Release Fertilizers (CRFs) are specialized fertilizers coated with a semipermeable membrane, designed to gradually release nutrients into the soil over time, providing a steady and predictable supply of essential nutrients to plants.These and other fertilizers are used by farmers around the world to increase yields and produce better crops. They can supply a wide range of nutrients, from the three basic macronutrients (nitrogen, phosphorus, and potassium), to a number of micronutrients that assist with plant growth. With many farmers concerned with nutrient use efficiency and environmental impact, many have chosen to utilize controlled release fertilizers. CRFs are granular fertilizers coated with a semipermeable membrane that gradually release nutrients into

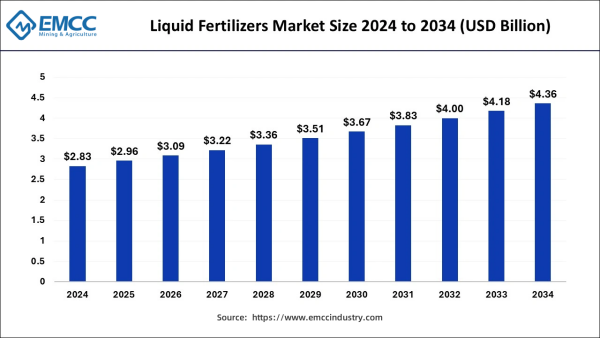

Liquid Fertilizers Market Size, Share, and Trends 2025 to 2034

The global liquid fertilizers market size is estimated at USD 2.96 billion in 2025 and is predicted to reach around USD 4.36 billion by 2034, accelerating at a CAGR of 4.42% from 2025 to 2034. The Asia Pacific liquid fertilizers market size surpassed USD 1.36 billion in 2025 and is expanding at a CAGR of 4.55% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year. Liquid Fertilizers Market Size and Forecast 2025 to 2034 The global liquid fertilizers market size was estimated for USD 2.83 billion in 2024 and is anticipated to reach around USD 4.36 billion by 2034, growing

Organic Fertilizers & Organic Production

The question “What is an organic fertilizer?” seems straightforward to answer, but as is often the case, the answer may be slightly more complicated than we initially thought. The dictionary defines ‘organic’ as “of, relating to, or derived from living organisms,” which seems clear enough. So, it might seem logical that an organic fertilizer would be a fertilizer that is “of, relating to, or derived from living organisms.” For example, a fertilizer created from animal waste, plant-based fertilizers such as compost, and biosolids. So, is that it? Have we answered the question? Well, not quite. Animal waste, such as manure, slurry, meat processing waste, and guano, may be used as

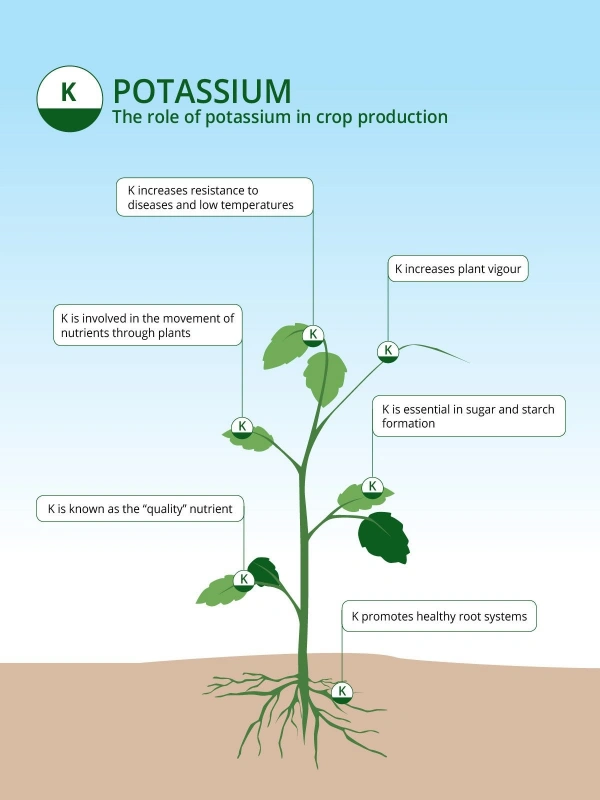

Potassium Based Fertilizers

Potassium (K) is one of the three essential plant macronutrients, along with nitrogen and phosphorus, that plants need to thrive. Choosing and using potassium-based fertilizers guarantees the availability of potassium in the soil, ready for plants to take up the relatively large amounts of the nutrient they require. Potassium increases crop yields and improves the quality of agricultural produce while also enhancing the ability of plants to resist diseases, insect attacks, cold and drought stresses, and other adverse conditions. By helping develop strong and healthy root systems, potassium increases the efficiency of the uptake and use of nitrogen and other nutrients. Potassium and Animal Nutrition And it is not just

Phosphorus Fertilizers

In the quest for sustainable agriculture, phosphorus fertilizers stand at the forefront of both challenge and opportunity. This vital nutrient, indispensable for plant development, requires careful management to maximize its benefits while minimizing its environmental impact. What Is Phosphorus Fertilizer? Phosphorus fertilizer is a nutrient-rich product that plays a crucial role in modern agriculture, supplying one of the three macronutrients essential for plant growth. As rain constantly washes phosphorus (P) from the soil, farmers rely on organic or synthetic fertilizers to replenish depleted reserves. Phosphorus drives key plant processes like energy and nutrient transport, photosynthesis, and cell division. The most prominent benefits of using phosphorus fertilizers are: robust root growth;

What Is Phosphate?

A Source of Essential Nutrients Phosphate and phosphorous are vital for life and growth. Discover how this rock is formed, what it’s used for, and why it is so important in feeding a growing world. Phosphate is the natural source of phosphorous, an element that provides a quarter of all the nutrients that plants need for their growth and development. Phosphorous is used in many products, and is an essential ingredient in all fertilizers. How is Phosphate Formed? Phosphate is a sedimentary rock formed millions of years ago by the accumulation of organic matter on the ocean floor. Phosphate reserves are found in Africa, North America, Kazakhstan, the Middle East

Potash Critical In Plant Stress Tolerance

As a leader in potash fertilizer production equipment and systems, we understand the vital role potassium-bearing fertilizers bring to the overall health and quality of plants. As it turns out, however, new research is revealing that potassium’s contribution to plant health is even more important than the industry initially thought; researchers are now finding that potassium also has a major influence on how plants tolerate stress. This finding has prompted much excitement, as a solution is desperately needed at a time when biotic and abiotic stresses on plants continue to escalate. Some experts anticipate that potassium will be especially important in tolerance to drought – a growing concern amidst the uncertainties of

The Bulk Solids Insider: Lithium’s Price Plummet, The Growing Phosphate Fertilizer Market, and Red Sea Shipping Challenges

Updates in Mining & Minerals Canada Grants Nunavut Control Over Mineral Resources The Arctic territory of Nunavut was granted control over its mineral resources by the Canadian government in a devolution that has been years in the making. The territory, rich in critical minerals and other resources, will now be able to collect royalties that would otherwise have gone to the federal government. Despite challenges in the region, the move could help to bolster exploration and development, according to Reuters. Future of Wyoming’s Trona Industry Uncertain All eyes in the soda ash industry continue to be on the Bureau of Land Management’s proposed Rock Springs Resource Management Plan (RMP), public comment

A Global Food Crisis

The scale of the current global hunger and malnutrition crisis is enormous. A total of 1.9 million people are in the grips of catastrophic hunger – primarily in Gaza and Sudan but also in pockets of South Sudan, Haiti and Mali. They are teetering on the brink of famine. In Zamzam camp in northern Sudan, famine has been confirmed. Many food crises involve multiple overlapping issues that are building year on year. What are the main causes of the global food crisis? Conflict A total 65 percent of the 343 million people facing acute hunger are in fragile or conflict-hit countries. Violence and instability in the Middle East, East, Central

The Bulk Solids Insider: Copper From Algae, Improvements in Zinc Nutrient Use Efficiency, and Extracting Value From Wastewater

Updates in Mining Chinese Copper Smelters to Lower Output Chinese copper smelters are expected to reduce production or extend maintenance in 2025 to cope with a major shortage of copper concentrate, according to Mining Weekly. The anticipated one million metric ton shortage is the result of global mine disruptions and rising smelter capacity and could see China’s copper smelting to drop to as low as 75% usage capacity. Critical Mineral Shortages Stifling Energy Transition Challenges in getting critical minerals are putting the global energy transition at risk according to new research from GlobalData. Mineral depletion, resource distribution, geopolitical tensions, and other factors are creating roadblocks in the face of unprecedented demand

FACTORS THAT INFLUENCE GRANULATION

Be it for a fertilizer or soil amendment product, the granulation process (and the many configurations thereof) requires a delicate balance of variables in order to economically produce a product that meets the desired qualities. Depending on the feedstock, the end product, and the process used, these factors can vary significantly. For this reason, testing is often an essential step in the development of a process for producing a granular soil amendment or fertilizer product. However, there are a few overarching themes that play into the success of any granulation operation, no matter what the product. These are outlined here. MEASURING GRANULATION SUCCESS It’s important to recognize that the “success”

Analysis of dry granulation and wet granulation in organic fertilizer industry

Overview of dry granulation technology Technical principle Dry granulation is a process of directly pressing dry organic materials into granules by physical extrusion, compression, etc. No wetting agent or binder is required, and the original nutrients and physical properties of the materials are retained. Process characteristics High cost-effectiveness: The dry granulation process is simple, energy-saving, and no additional drying steps are required, thereby reducing production costs. Good nutrient retention: Since no wetting agent is required, dry granulation can effectively retain nutrients such as nitrogen, phosphorus, and potassium in organic materials, making fertilizers easier for plants to absorb and utilize. Strong stability: The granules made by the dry method have high

Fertilizer Granulation Opens Opportunities in Precision Agriculture

Fertilizer granulation has long played an important role in helping growers to maximize their yields while improving nutrient handling and application, but with precision agriculture’s growing adoption, granular fertilizers have become more important than ever. What is Precision Agriculture? Precision agriculture, or ‘precision farming’, combines innovations in geolocation technology with recognized best management practices in crop production to deliver site-specific, optimized crop nutrition, based on the identification and analysis of in-field variability. As such, it is an essential technique in meeting global food demand amidst ongoing challenges in agriculture. The underlying principle behind precision agriculture is that variability naturally occurs within fields. Therefore, applying the proper inputs in the right place,

Fertilizer Prices Edge Lower Amid Lower Input Costs and Improved Production Prospects

This is part of a special series based on the April 2024 edition of the Commodity Markets Outlook, a flagship report published by the World Bank. This series features concise summaries of commodity-specific sections extracted from the report. The World Bank’s fertilizer price index remained relatively stable during the second quarter of 2024, following a 20 percent drop in the first quarter. The index is 24 percent lower than it was a year ago, primarily due to a significant decline in phosphate rock prices (-56 percent) and potassium prices (-17 percent). This broad weakness is attributed to improved production prospects driven, for the most part, by lower input costs. In

COMPLEX FERTILIZERS VS BLENDS

INTRODUCTION Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) is an engineering and equipment manufacturer. We are known as the material experts, able to solve all sorts of material processing and handling problems, and now serve nearly every industry, from energy and agriculture, to mining and minerals. EMCC has become the premier name in providing feasibility testing, process and product design, and custom processing equipment for fertilizer blending and granulation. From idea, to complete process solutions and custom processing equipment, we offer unparalleled capabilities in fertilizer blending and granulation. COMPLEX FERTILIZERS VS BLENDS The area that has seen significant change is in the use of complex fertilizers over

Cat litter granulation line: EMCC customized solution

Automated and intelligent production mode Modern cat litter production lines integrate advanced automation technology and intelligent management systems. From raw material processing to final product packaging, every production link strives for excellence. The automated equipment on the production line covers the crushing, pelletizing, drying, screening, coating and packaging of raw materials, ensuring the purity and uniformity of cat litter particles, while also greatly improving production efficiency and reducing the need for manual operation, thereby reducing production costs. At the same time, environmental protection and energy-saving technologies have also become the focus of industry attention. Modern production facilities use dust-free and deodorizing technologies to meet consumers’ demand for high-quality, environmentally friendly

Automation and intelligentization of cat litter production line

With the rapid development of the pet industry, cat litter production technology is undergoing significant changes. Modern cat litter production lines widely use automation and intelligent technologies to improve production efficiency and product quality. Modern cat litter production lines use cutting-edge automation technology and intelligent management systems to finely manage and strictly control every link from raw material crushing, grinding, pelletizing, drying, screening to packaging. This innovation not only ensures the purity and uniformity of cat litter products, but also significantly improves production efficiency and reduces labor costs. The power of science and technology is fully reflected here, and every grain of cat litter carries deep care for the healthy

Mannheim potassium sulfate production line helps global agricultural development: technology and environmental protection are equally important

In recent years, the global demand for high-efficiency fertilizers has continued to grow, especially the market demand for high-quality fertilizers such as potassium sulfate (SOP). Potassium sulfate is widely used in salt-sensitive crops such as tobacco, tea trees and potatoes due to its chlorine-free characteristics. As the mainstream process for producing potassium sulfate, the Mannheim potassium sulfate production line is ushering in new development opportunities with its mature technology and environmental protection performance. Technical advantages of the Mannheim process The Mannheim process uses potassium chloride and sulfuric acid as the main raw materials to generate potassium sulfate and by-product hydrogen chloride through high-temperature reaction. This process is simple and efficient,

Mannheim potassium sulfate production line: the core driving force of the fertilizer industry

As the global demand for high-efficiency fertilizers continues to grow, the Mannheim potassium sulfate production line has become one of the key technologies for fertilizer manufacturers. As a high-quality potassium fertilizer, potassium sulfate can effectively increase crop yields and improve soil structure, so it is widely used in agricultural production. This article combines product information from several chemical equipment companies to explore the latest developments and characteristics of the Mannheim potassium sulfate production line. Advantages of process technology The Mannheim potassium sulfate production process uses potassium chloride and sulfuric acid as the main raw materials to generate potassium sulfate and hydrogen chloride gas through high-temperature reactions. The characteristics of this

Compost Turners Help Revolutionize Farm Waste Management

As the agricultural industry’s demand for sustainable development and green technology increases, compost turners have quickly become the “star equipment” for farm waste management. This equipment can accelerate the compost decomposition process by regularly turning the composting materials to achieve sufficient oxygen flow. Compared with traditional composting methods, the use of compost turners is not only more efficient, but also can significantly improve the quality of compost while reducing labor costs. On farms around the world, more and more farmers are beginning to use compost turners to deal with discarded straw, fallen leaves and livestock and poultry manure. This equipment uses powerful mechanical force to quickly mix and break up

HOW DOES THE SPRAY TOWER TREAT THE WASTE GAS OF THE RUBBER FACTORY!

In the production process of rubber products, a large amount of hydrogen sulfide waste gas will be generated. Hydrogen sulfide is a strong neurotoxin and has a strong stimulating effect on the mucous membrane. Hydrogen sulfide is flammable and can form an explosive mixture when mixed with air, which can cause combustion and explosion in case of open fire and high heat energy. Reacts violently with concentrated nitric acid, fuming sulfuric acid or other strong oxidants, resulting in an explosion. The gas is heavier than air and can spread to a considerable distance at a lower place, causing flashback in case of an open flame. Hydrogen sulfide exhaust gas will

Drum coolers help improve fertilizer production efficiency and promote green manufacturing

With the continuous upgrading of fertilizer production technology, the rotary cooler is becoming one of the indispensable core equipment in the fertilizer production line. This efficient cooling equipment can not only quickly reduce the temperature of granular fertilizers and ensure the quality of fertilizers, but also greatly improve production efficiency and help the green manufacturing of the fertilizer industry. The drum cooler is a rotary equipment that evenly cools the hot fertilizer particles in the drum to avoid quality problems or the risk of spontaneous combustion caused by excessive temperature during subsequent packaging and storage. The head of the technical department of a well-known fertilizer equipment company pointed out: “The

Organic and inorganic compound fertilizers lead the green revolution in modern agriculture

As the global call for sustainable agricultural development grows louder, organic-inorganic compound fertilizers have gradually become a hot topic in modern agriculture. By combining organic and inorganic nutrients, this type of fertilizer can not only increase crop yields, but also protect and improve the soil and reduce environmental pollution caused by the use of chemical fertilizers. Agricultural experts point out that organic-inorganic compound fertilizers are formed by combining organic matter made from animal and plant waste with inorganic nutrients in chemical fertilizers to form a multi-effect synthetic fertilizer. This type of fertilizer can provide fast-acting and long-term nutritional support for crops. Inorganic components can quickly release nutrients to meet the

Mineral powder granulation production line equipment: innovative technology promotes high efficiency and environmental protection

With the continuous progress of industrial production, mineral powder granulation production line equipment is ushering in a technological innovation to meet the growing market demand. Granulation equipment not only improves the quality and uniformity of mineral powder particles, but also significantly improves the environmental performance of production by reducing energy consumption and reducing pollutant emissions. The demand for these high-efficiency equipment is increasing in many industries, especially in the fields of metallurgy, building materials and chemicals. Disc granulator: high efficiency and environmental protection in parallel As one of the core equipment of mineral powder granulation equipment, the disc granulator has attracted much attention due to its large production capacity and

Technology upgrade and market demand of global mineral powder granulation production line

With the expansion of mineral powder application fields, the demand for mineral powder granulation production line has increased significantly, becoming an important driving force for the development of multiple industrial fields. Mineral powder granulation technology is widely used in metallurgy, building materials, chemical industry and other industries. Its core goal is to improve the storage and transportation performance of mineral powder through granulation process, while improving product quality and economic benefits. Diversification of granulation technology At present, the main processes of mineral powder granulation include drum granulation, spray granulation and extrusion granulation. Among them, drum granulation is widely used due to its large processing capacity and continuous production characteristics, and

Composting projects promote sustainable agricultural development and environmental protection

As more and more cities implement composting projects, waste management is undergoing a revolutionary change. Composting has become a key means to effectively reduce food waste and promote sustainable agricultural development. By converting kitchen waste and garden waste into organic fertilizer, composting not only improves soil health but also reduces methane emissions in landfills. A large number of composting projects have begun to cooperate with local farms to provide nutrient-rich organic matter for orchards, vegetable plots and gardens. These composts not only enhance the soil’s water retention capacity, significantly increase crop yields, especially during droughts, but also reduce dependence on chemical fertilizers, bringing more environmentally friendly agricultural solutions. In addition,

High-efficiency organic and inorganic compound fertilizer production line equipment helps agricultural transformation and upgrading

As global agriculture develops towards intelligence and efficiency, organic-inorganic compound fertilizer production line equipment is becoming the core force to promote agricultural transformation. This new production line equipment combines the precise ratio of organic and inorganic components with efficient and automated production technology, providing strong technical support for agricultural production. At present, many leading fertilizer equipment manufacturers at home and abroad have launched the latest compound fertilizer production line equipment, which can mix, granulate and automatically package organic and inorganic nutrients in a short time. This not only greatly improves the efficiency of fertilizer production, but also ensures the quality stability and nutritional uniformity of each batch of fertilizer. EMCC

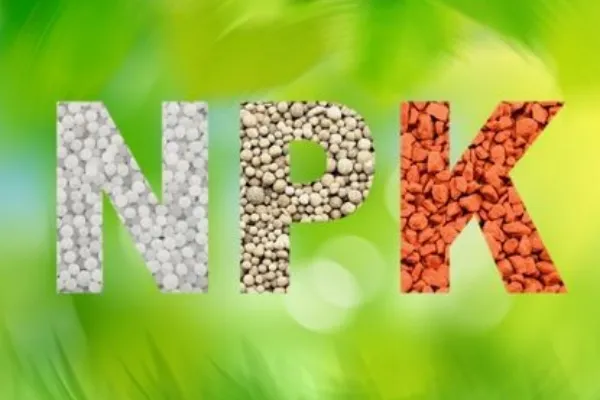

WHAT ARE THE EFFECTS OF NPK FERTILIZERS ON PLANT GROWTH

In the process of plant growth, there is no need for nutrients. There are large and micronutrient elements. At the same time, some plants also need some regulators to promote growth. What things contain nitrogen, phosphorus and potassium? Effects of phosphorus, potassium and nitrogen on plants 1. Nitrogen fertilizer: Nitrogen in the material is the function of nitrogen element, which can promote the lush growth of plant stems and leaves, and the leaves are dark green. The effect is obvious in the early stage of plant growth, which is why many plants apply nitrogen fertilizer heavily in the early stage of flower, and nitrogen element accounts for a large proportion

WHAT ARE THE MICROBIAL INOCULANTS COMMONLY USED IN THE PRODUCTION OF BIO-ORGANIC FERTILIZERS?

In the fermentation process of organic fertilizer, the bacteria required are bacteria, fungi, actinomycetes, etc. What are the functions and differences of these microbial agents? Among them: Bacteria – quickly absorb soluble and easily decomposed organic matter, and play a major role in the temperature rise of fermentation. Actinomycetes – decompose cellulose, dissolve lignin, the ability to decompose cellulose is not as good as that of fungi, but it is more resistant to high temperature and pH than fungi, and it is the dominant bacteria to decompose cellulose lignin during high temperature period. And can produce some antibiotics, inhibit the growth of some harmful bacteria. Fungi–decompose lignin, cellulose. The optimum

EXTRUSION GRANULATOR REALIZES GRANULATION OF VARIOUS MATERIALS

The drying-free compound fertilizer production line adopts the drying-free compound fertilizer extrusion granulation process: the solid material is agglomerated by increasing the pressure. Extrusion granulation is actually used for the production of crystalline products, powders, and organic raw materials, and is most suitable for heat-sensitive materials. Applicable materials are: 1. Fertilizers: potassium sulfate, ammonium bicarbonate, potassium chloride, urea, Russian red potassium, NPK compound fertilizer, ammonium chloride, potassium nitrate, monoammonium phosphate, diammonium phosphate, ammonium sulfate, ammonium bicarbonate, magnetic fertilizer, etc. ; 2. Powder materials: ferric oxalate, melamine cyanurate, antioxidants, bromochlorohydantoin, sodium chloride, sodium dichloroisocyanurate, sodium trichloroisocyanurate, cyanuric acid, bleaching powder, zinc oxide , lead oxide, potassium carbonate, strontium carbonate, calcium chloride, calcium hydrogen

ORGANIC FERTILIZER EQUIPMENT TURNS PIG MANURE INTO TREASURE

In recent years, with the continuous deepening of the concept of environmental protection, the traditional breeding mode has the problems of “scattering, chaos and pollution”, which can no longer meet the development requirements of the breeding industry of the times. In order to adapt to th development of the times, many environmental protection facilities have appeared, such as fermentation turner,mixing mixer, organic fertilizer granulator,etc., which can effectively solve the environmental pollution caused by organic wastes in livestock and poultry breeding industries, reduce the eutrophication of surface water caused by pollution, and help improve the safety and quality of agricultural products. It has laid a good foundation for human beings to

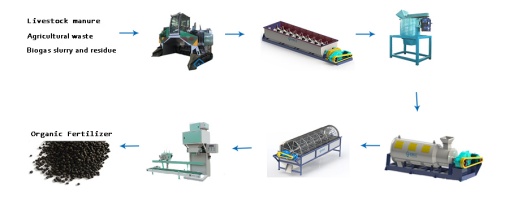

THE DETAILED PROCESS OF PRODUCING LIVESTOCK MANURE ORGANIC FERTILIZER BY DRUM GRANULATION PROCESS

1. Transport the treated poultry manure (cattle, sheep, chicken manure, etc.) directly to the raw material mixer; 2. Transported to the drum granulator, and steam (or water) is introduced at the same time. The material forms a rolling material bed by the friction generated by the rotation of the drum granulator, and the extrusion force generated by rolling makes it contain a certain liquid phase. The materials agglomerate into small particles, these small particles become the core, and adhere to the surrounding powder to form qualified particles; 3. Transport to the organic fertilizer dryer for heat exchange with the heat from the hot blast stove; 4. Transported to the hot

THE DEVELOPMENT HISTORY OF VERTICAL CHAIN CRUSHER

Compound fertilizer is the fastest growing fertilizer variety in my country in recent years. In the production of powdery and granular phosphate fertilizers and compound fertilizers, the selected crusher is mainly used for the crushing of raw materials and large and large semi-finished products, especially suitable for superphosphate, heavy superphosphate, compound fertilizer, ammonium phosphate, nitro Phosphate fertilizers, etc. typical. These materials are easy to absorb moisture and have high viscosity. In the crushing process, they are easy to stick to the inner wall of the casing, causing the machine to block, frequent shutdowns for cleaning, and the material stuck to the inner wall of the casing is hard and difficult

What wrong behaviors will reduce the efficiency of BB fertilizer

BB fertilizer, also known as formula fertilizer, is a high-quality and high-efficiency compound fertilizer composed of three or more single-grain fertilizers, namely nitrogen, phosphorus, potassium or other elements. As a physicochemical technology of formula fertilization, BB fertilizer is conducive to accelerating the popularization and application of formula fertilization technology in rural areas. Places that should be paid attention to during fertilization 1. Pay attention to moisture-proof to prevent nitrogen volatilization or agglomeration. 2. Pay attention to uniformity. If there is delamination, it should be shaken up and down; in case of agglomeration, use a wooden stick or a wooden hammer to smash it before use, otherwise the unevenness will affect

HOW DO FARMS TREAT COW DUNG INTO ORGANIC FERTILIZER

There is a farm with 300 cattle. The fecal output of 300 cattle is nearly 10 tons a day, about 3650 tons a year. The emission of farm manure has always been a difficult problem of environmental pollution. It costs millions to buy pollution treatment equipment, which is not cost-effective for farmers. Cow dung cannot be directly applied to the ground without fermentation and decomposition. Direct application will cause serious problems such as burning seedlings and dead trees. With the promotion and popularization of the policy of replacing chemical fertilizer with organic fertilizer. The processing of cow dung into organic fertilizer not only solves the problem of livestock manure emission

COMPARISON OF MECHANICAL PACKAGING AND MANUAL PACKAGING

The fertilizer packaging machine is an automatic high-tech product designed for the packaging of granular loose materials such as BB fertilizer, compound fertilizer, chemical raw materials, rice, feed, chemical fertilizer, etc. It consists of scale, feeder, weighing hopper, unloading hopper and air bag. It consists of fixtures, sensors, weighing control instruments and electronic control systems. All automated control processes except manual bagging can be realized. So, what are the advantages of the packaging machine? 1. Reduce labor intensity and improve working conditions The automatic weighing and packaging machine can free workers from stress and heavy repetitive work, avoid and reduce the effects of highly toxic, irritating, corrosive, low temperature, humidity,

WHAT SHOULD BE PAID ATTENTION TO IN THE SELECTION OF HEAT SOURCE FOR ENERGY-SAVING PIG MANURE ORGANIC FERTILIZER DRYER?

The selection of heat source is very important for pig manure organic fertilizer drying equipment, not only to ensure the problem of meeting the emission standards, but also to consider the operating cost. Buying a suitable heat source can increase the actual effect of drying and greatly reduce the operating cost of the pig manure organic fertilizer drying equipment. As an energy-saving pig manure organic fertilizer drying equipment, what should people pay attention to when choosing a heat source? 1. Ensure the dry quality of pig manure. The quality of the finished product determines the quality of the energy-saving pig manure organic fertilizer drying equipment. Excellent heat source and calorific

Phosphorus Fertilizers

In the quest for sustainable agriculture, phosphorus fertilizers stand at the forefront of both challenge and opportunity. This vital nutrient, indispensable for plant development, requires careful management to maximize its benefits while minimizing its environmental impact. What Is Phosphorus Fertilizer? Phosphorus fertilizer is a nutrient-rich product that plays a crucial role in modern agriculture, supplying one of the three macronutrients essential for plant growth. As rain constantly washes phosphorus (P) from the soil, farmers rely on organic or synthetic fertilizers to replenish depleted reserves. Phosphorus drives key plant processes like energy and nutrient transport, photosynthesis, and cell division. The most prominent benefits of using phosphorus fertilizers are: robust root growth;

Rotary Kilns vs. Rotary Dryers: What’s the Difference?

When it comes to thermal processing, confusion often arises in choosing between a rotary kiln and rotary dryer. Although these two types of equipment share similar thermal processing principles, they are used in very different applications: Rotary dryers are used for drawing moisture out of a material. As such, they typically operate at temperatures between 800º – 1400ºF. In contrast, rotary kilns are used to cause a chemical reaction or phase change, requiring them to operate at much higher temperatures, typically between 1000º – 3000ºF. Some moisture reduction may occur during processing in a rotary kiln, but this is typically secondary to the primary goal. In other words, while rotary kilns can help to

Rotary Drum Granulator Frequently Asked Questions (FAQs)

Rotary drum granulators, also known as agglomeration or granulation drums, are pivotal to a wide array of industrial processes, helping producers working with bulk solids to condition and agglomerate their materials for downstream processing, easier handling, and improved performance. In selecting agglomeration/granulation equipment and evaluating the fit of a drum granulator for a given process, many questions may arise. What follows are some of the most frequently asked questions we field in the process of helping our customers bring their granulation processes to life. How does a rotary drum granulator work? A drum granulator works by tumbling material in the presence of a liquid binder to encourage granule formation and

Why is MKP widely used for foliar applications all over the world?

The power of MKP fertilizer in foliar applications to improve crop yield and quality explains its popularity for open-field, orchard and protected crops. Supplying plants with adequate nutrition is essential for optimum crop performance, and foliar fertilization is now a well-established method of delivering plant nutrients in open-field, orchard, and controlled cropping environments. While many foliar fertilizers include nitrogen, the value of a nitrogen-free foliar application, such as a high-quality MKP (monopotassium phosphate) water-soluble fertilizer, should not be underestimated. What is MKP fertilizer? Monopotassium phosphate (MKP) fertilizer is a fully water-soluble potassium and phosphorus (PK) fertilizer that contains 52% P2O5 and 34% K2O. Because MKP fertilizer consists entirely of these

A Detailed Look At Limestone Drying

Limestone drying, typically carried out in rotary dryers, is utilized throughout this industrial mineral’s lifecycle, from quarrying to finished product. The following explores why drying is essential for quality limestone, its role in production, key considerations, and the importance of testing and equipment design for a reliable drying process. Why Dry Limestone? Whether destined for use as a fertilizer, building material, or other use, quarried limestone may go through a range of different processes to prepare the material for its end use. Drying is one of the first and most critical steps, playing an integral role in allowing limestone producers to optimize their production lines, bring a salable product to market, and ensure

Limestone Granulating – Material Characteristics to Consider

While granulating limestone has become common practice for the many advantages it can offer, the process requires careful engineering to ensure a consistently reliable, continuous operation with maximum on-size yield. A number of material characteristics come into play. The Limestone Granulating Process The most common setup for a limestone granulating plant utilizes a mixer and disc granulator combination, an approach that not only maximizes on-size yield, but also leaves producers with a highly refined product. This type of setup relies on the principles of wet granulation, or agitation agglomeration, in which a liquid binder is employed, alongside a tumbling motion, to convert powders and fines into spherical granules in an

Fertilizer Numbers – What Is NPK

Looking at fertilizers in the store, you’ll usually find a grouping of numbers on the label. The numbers are important, and are required by law in most places. The numbers provide important information about what types of nutrients the fertilizer offers, and how much of each it contains. What Do the Numbers on Fertilizer Mean? Typically, there are three numbers on a fertilizer label separated by dashes, representing the percentage of N, P and K. What is NPK in fertilizer? Those three numbers correlate with the value of the three macro-nutrients used by plants: These macro-nutrients are nitrogen (N), phosphorus (P), and potassium (K), or NPK for short. Understanding the meaning of NPK will help you

Potash Critical In Plant Stress Tolerance

As a leader in potash fertilizer production equipment and systems, we understand the vital role potassium-bearing fertilizers bring to the overall health and quality of plants. As it turns out, however, new research is revealing that potassium’s contribution to plant health is even more important than the industry initially thought; researchers are now finding that potassium also has a major influence on how plants tolerate stress. This finding has prompted much excitement, as a solution is desperately needed at a time when biotic and abiotic stresses on plants continue to escalate. Some experts anticipate that potassium will be especially important in tolerance to drought – a growing concern amidst the uncertainties of

DIRECT VS. INDIRECT DRYING

Direct dryers are used more frequently than their indirect counterparts, because of the efficiency they offer. And while direct rotary dryers are most often the selected drying method, indirect rotary dryers are a valuable alternative for specific processing requirements. OPERATION While both types of dryers are comprised of a rotating drum in which the processing occurs, these two types of dryers utilize very different methods to process the material. Direct dryers rely on direct contact between the material and drying air to efficiently dry materials. Efficiency is further increased by the addition of lifting flights affixed to the internal walls of the dryer. Conversely, indirect dryers do not utilize direct

PELLETIZING VS. COMPACTION GRANULATION

When it comes to agglomerating material fines, compaction granulation and pelletization are often both investigated. Both methods are an effective solution, but each has distinct advantages and disadvantages. And while operating and capital costs are often the deciding factor between the two, there are many things to consider when choosing which method best suits your material and processing needs. Additionally, some materials may respond well to only one of these methods, making the choice clear. Other materials, however, will respond well to both (such as bentonite, coal, humate, potash, urea, and others) and will require further consideration. ADVANTAGES TO PELLETIZING FASTER NUTRIENT DELIVERY Because pellets are not created through pressure,

Co-Current Vs. Counter Current Drying

Many factors are taken into consideration when designing a rotary drum dryer that can both efficiently and effectively dry a material. Factors such as the material’s bulk density, heat sensitivity, particle size, and flowability, among others, all interact to influence how the material will behave in the dryer, and subsequently, how the dryer should be designed to optimally work with those characteristics. One critical factor in designing a rotary dryer that produces the desired end product characteristics is the air flow configuration, or the direction in which the process gas flows through the dryer in relation to the material. Rotary dryers are available in two types of air-flow configurations: co-current and counter

Pros and Cons of Granular and Liquid Fertilizers

Theoretically, plants can’t tell the difference between nutrients supplied by the granular and liquid fertilizers, but they both have advantages depending on the farming application. There are several ways to categorize fertilizers. One logical way to look at them is as “granulars” and “liquids”. For the purposes of this comparison, anhydrous ammonia (technically a liquid) will not be considered. Dry fertilizers are generally incorporated into granules. Fertilizer blends can be created by mixing individual granular fertilizer of known analysis (e.g., 46-0-0, 18-46-0 and 0-0-60) in the proper ratio to create the desired blend. Dry fertilizers can be ground applied as a broadcast; applied at planting as a band, often placed

CONCURRENT VS. COUNTERCURRENT DRYERS

INTRODUCTION Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as “EMCC”) is an engineering and equipment manufacturer. We are known as the material experts, able to solve all sorts of material processing and handling problems, and now serve nearly every industry, from energy and agriculture, to mining and minerals. EMCC has become the premier name in providing feasibility testing, process and product design, and custom processing equipment for drying requirements. From idea, to complete process solutions and custom processing equipment, we offer Concurrent vs. Countercurrent Dryers. CONCURRENT VS. COUNTERCURRENT DRYERS There are two basic types of Direct Fired Dryers: Concurrent (or parallel flow) Countercurrent (or counter flow) In both types

Warning | Uncomposted livestock manure is not organic fertilizer! It is garbage!

Only decomposed livestock manure can be called organic fertilizer. Undecomposed livestock manure can be called garbage or harmful fertilizer. So how can we turn manure into organic fertilizer? What are the harms of undecomposed organic fertilizer to fruits and vegetables? Let’s discuss it together. During the composting process, the poultry and livestock manure, through the action of microorganisms, turns the organic matter that is difficult to be used by crops into nutrients that are easy to be absorbed by crops, which can be called organic fertilizer. The high temperature of about 70℃ generated during the composting process can kill most pathogens and insect eggs, basically achieving harmlessness. Ⅰ. The possible

EMCC R&D LAB: CHICKEN LITTER TO ORGANIC FERTILIZER GRANULE

After batch agglomeration testing were conducted on small samples of the material to determine initial feasibility, continuous testing was carried out successfully by the EMCC R&D team. The spherical pellet produced by our granulation technique and equipment was exactly what the customer was looking for. As one kind of dust free pellet, it’s capable of being blended with other fertilizers to create improved blends. With the granulation technique and equipment from EMCC Industry,this turnkey fertilizer granulation plant project will allow our customer to produce the desired fertilizer granule on their own.

Best Practices for Maintaining a Disc Granulator

The disc granulator, also known as a pan granulator, is a preferred approach to agitation agglomeration (wet granulation) for soil amendment producers, mineral processors, and chemical manufacturers, favored for its high on-size yield, ability to fine-tune product, and the premium round granules it produces. And while this diverse machine is relatively low-maintenance, it does require some routine upkeep and regular inspections as part of a preventive maintenance program. Having the proper maintenance procedures in place will help to ensure the disc granulator continues to run as designed, promoting process efficiency, product uniformity, and equipment longevity. This proactive approach to maintenance also encourages a safe work environment and helps to avoid costly

Rotary Coolers In Fertilizer Production

Product cooling is often a vital step in the production of fertilizers, helping to ensure product integrity and reduce potential hazards. Rotary coolers are the equipment of choice for fertilizer production plants, offering a host of benefits. The following covers the important role cooling plays in fertilizer production, and why rotary coolers are best suited for the job. THE ROLE OF ROTARY COOLERS IN FERTILIZER PRODUCTION Not all fertilizer production lines employ a cooling step. Depending on the type of material, and downstream handling requirements, cooling is not always necessary. However, when certain conditions exist, product cooling is essential. PROTECTING DOWNSTREAM EQUIPMENT & EMPLOYEES As part of product finishing, fertilizer granules

Compost Turners Help Revolutionize Farm Waste Management

As the agricultural industry’s demand for sustainable development and green technology increases, compost turners have quickly become the “star equipment” for farm waste management. This equipment can accelerate the compost decomposition process by regularly turning the composting materials to achieve sufficient oxygen flow. Compared with traditional composting methods, the use of compost turners is not only more efficient, but also can significantly improve the quality of compost while reducing labor costs. On farms around the world, more and more farmers are beginning to use compost turners to deal with discarded straw, fallen leaves and livestock and poultry manure. This equipment uses powerful mechanical force to quickly mix and break up

HOW DOES THE SPRAY TOWER TREAT THE WASTE GAS OF THE RUBBER FACTORY!

In the production process of rubber products, a large amount of hydrogen sulfide waste gas will be generated. Hydrogen sulfide is a strong neurotoxin and has a strong stimulating effect on the mucous membrane. Hydrogen sulfide is flammable and can form an explosive mixture when mixed with air, which can cause combustion and explosion in case of open fire and high heat energy. Reacts violently with concentrated nitric acid, fuming sulfuric acid or other strong oxidants, resulting in an explosion. The gas is heavier than air and can spread to a considerable distance at a lower place, causing flashback in case of an open flame. Hydrogen sulfide exhaust gas will

COMPOUND FERTILIZER EQUIPMENT- ROTARY COATING MACHINE

When the organic fertilizer production line produces high-end fertilizers, the coating machine plays a pivotal role as the last process before packaging. It is responsible for the further polishing and processing of the finished fertilizer, making it a leap forward in appearance and even efficacy as a commercial fertilizer. The coating machine is used for the coating and coating process of compound fertilizer and organic fertilizer. The organic fertilizer coating machine is a small drum similar in appearance to a dryer, but there are no lifting plates and other components inside. When using, it must be equipped with a powder sprayer or a coating tank in front of the coating

WORKING PRINCIPLE OF ROULETTE TYPE ORGANIC FERTILIZER TURNER

The roulette type turning and throwing machine is driven by a chain in the middle, which drives two large-diameter turning and throwing roulettes for symmetrical turning. Equipped with no dead angle, adjustable speed, displaceable trolley, which is convenient for left and right displacement, and ensures that the equipment can complete large-span flipping work with low energy consumption. In the case of deep stacking of materials, the special energy-saving transmission mechanism uses less power to complete the high-depth and large-span tumbling operation. Its hydraulic lifting system can automatically lift the turning wheel to ensure that the equipment can move without obstacles. At the same time, the supporting fully automatic electrical control

THE TROUGH COMPOSTER EFFECTIVELY SHORTENS THE FERMENTATION TIME

The groove type compost turner is used for the fermentation and turning of organic waste such as livestock manure, sludge garbage, sugar factory filter mud, slag cake and straw sawdust, and is widely used in organic fertilizer plants, compound fertilizer plants, Fermentation and dewatering operations in sludge garbage plants, gardening farms, and bisporus mushroom planting plants. The groove type compost turner is composed of main components such as transmission device, lifting device, walking device, stacking device, transfer car and so on. The motor directly transmits the power to the cycloid pin gear reducer, which is transmitted to the turning drum through the sprocket. The turning and throwing fins on the drum

FILTER DUST COLLECTOR—–BAG DUST COLLECTOR

The filter type dust collector refers to the equipment that realizes the separation of gas and solid when the dust-containing flue gas pores pass through the filter layer, and the dust particles in the airflow are blocked and captured by the filter layer. The filter type dust removal device includes a bag filter and a particle layer filter. The former usually uses a filter bag made of organic fiber or inorganic fiber fabric as a filter layer, while the latter filter layer uses particles of different particle sizes, such as quartz sand, It is composed of river sand, ceramsite and slag. A bag filter is a dry dust filtration device

Drum coolers help improve fertilizer production efficiency and promote green manufacturing

With the continuous upgrading of fertilizer production technology, the rotary cooler is becoming one of the indispensable core equipment in the fertilizer production line. This efficient cooling equipment can not only quickly reduce the temperature of granular fertilizers and ensure the quality of fertilizers, but also greatly improve production efficiency and help the green manufacturing of the fertilizer industry. The drum cooler is a rotary equipment that evenly cools the hot fertilizer particles in the drum to avoid quality problems or the risk of spontaneous combustion caused by excessive temperature during subsequent packaging and storage. The head of the technical department of a well-known fertilizer equipment company pointed out: “The

WHAT ARE THE PRODUCTION LINES OF ORGANIC FERTILIZER EQUIPMENT? HOW MUCH SPACE WOULD IT TAKE TO BUILD ONE?

The floor area of organic fertilizer equipment is mainly related to the annual output, which is generally divided into the following types: The annual output of 5000 tons of organic fertilizer processing plant needs 1000-1500 square meters; The annual output of 10,000 tons of organic fertilizer processing plant needs 1500-2000 square meters; The annual output of 20,000 tons of organic fertilizer processing plant needs 2000-2500 square meters; The annual output of 30,000 tons of organic fertilizer processing plant needs 3000-3500 square meters; The annual output of 50,000 tons of organic fertilizer processing plant needs 5000-6000 square meters;

THE USE METHOD AND PARAMETERS OF THE DISC GRANULATOR

The disc granulator can produce spherical pure organic fertilizer, organic-inorganic fertilizer, and bio-organic fertilizer; the particles are uniform, smooth, round, with high strength and good fluidity. The following EMCC will show you how to use the disc granulator and its parameters: 1. How to use the disc granulator 1). Start up: Before starting up, check whether the reducer is filled with gear oil and whether the rotation direction of the disc is correct. 2). Operation: After pressing the start button, the host starts, and observe whether the equipment is operating normally, whether there is vibration, and whether the rotation is stable. 3). Filling: After the equipment is running normally, it

LARGE-SCALE ORGANIC FERTILIZER EQUIPMENT PRODUCTION ENTERPRISES

Organic fertilizer equipment can effectively solve the environmental pollution caused by organic wastes in livestock and poultry breeding and other industries, reduce the eutrophication of surface water caused by pollution, help improve the safety and quality of agricultural products, lay a good foundation for human beings to eat green food and organic food in an all-round way, and have remarkable ecological and environmental benefits. The production line of organic fertilizer is mainly divided into: pre-treatment part and granulation production part. The pre-treatment part is also called powder organic fertilizer processing equipment: fermentation pile turning machine, organic fertilizer pulverizer, drum screening machine and other equipment. The granulation part is: mixer, organic

High-efficiency organic and inorganic compound fertilizer production line equipment helps agricultural transformation and upgrading

As global agriculture develops towards intelligence and efficiency, organic-inorganic compound fertilizer production line equipment is becoming the core force to promote agricultural transformation. This new production line equipment combines the precise ratio of organic and inorganic components with efficient and automated production technology, providing strong technical support for agricultural production. At present, many leading fertilizer equipment manufacturers at home and abroad have launched the latest compound fertilizer production line equipment, which can mix, granulate and automatically package organic and inorganic nutrients in a short time. This not only greatly improves the efficiency of fertilizer production, but also ensures the quality stability and nutritional uniformity of each batch of fertilizer. EMCC

WHAT ARE THE EFFECTS OF NPK FERTILIZERS ON PLANT GROWTH

In the process of plant growth, there is no need for nutrients. There are large and micronutrient elements. At the same time, some plants also need some regulators to promote growth. What things contain nitrogen, phosphorus and potassium? Effects of phosphorus, potassium and nitrogen on plants 1. Nitrogen fertilizer: Nitrogen in the material is the function of nitrogen element, which can promote the lush growth of plant stems and leaves, and the leaves are dark green. The effect is obvious in the early stage of plant growth, which is why many plants apply nitrogen fertilizer heavily in the early stage of flower, and nitrogen element accounts for a large proportion

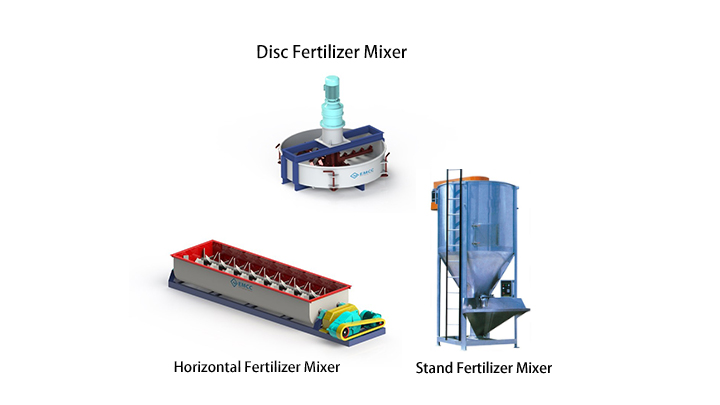

CLASSIFICATION OF ORGANIC FERTILIZER MIXERS

The vertical disc mixer is a special mixer for the fertilizer industry. It is a kind of mixing equipment specially used for organic fertilizer mixer produced by our company, with advanced design concept, compact machine and high practicability. The equipment consists of a stirring plate, a discharge port, a stirring arm, a bracket, a gear box and a transmission mechanism. It has the advantages of long service life, fast stirring speed, high mixing uniformity and thorough discharge. The double shaft mixer is the main equipment for the production of organic fertilizer, which is used for mixing and stirring the raw materials of organic fertilizer. The dual-shaft mixer uses the synchronous

WHAT ARE THE MICROBIAL INOCULANTS COMMONLY USED IN THE PRODUCTION OF BIO-ORGANIC FERTILIZERS?

In the fermentation process of organic fertilizer, the bacteria required are bacteria, fungi, actinomycetes, etc. What are the functions and differences of these microbial agents? Among them: Bacteria – quickly absorb soluble and easily decomposed organic matter, and play a major role in the temperature rise of fermentation. Actinomycetes – decompose cellulose, dissolve lignin, the ability to decompose cellulose is not as good as that of fungi, but it is more resistant to high temperature and pH than fungi, and it is the dominant bacteria to decompose cellulose lignin during high temperature period. And can produce some antibiotics, inhibit the growth of some harmful bacteria. Fungi–decompose lignin, cellulose. The optimum

CHARACTERISTICS OF CHICKEN MANURE DRYER EQUIPMENT

Chicken manure dryer is suitable for large, medium and small chicken farms and areas with developed breeding industry. According to the requirements of drying products, different heat sources can be used. Such as: gas generator, direct heating hot blast stove, indirect hot blast stove, heat transfer oil, electric heating, steam, etc. This machine is suitable for chicken manure, duck manure, livestock manure, slaughter leftovers, etc. with water content less than 65%. It has a good effect on opening up feed resources, reducing feeding costs and reducing environmental pollution. . Main features of chicken manure dryer: 1. Production process: This machine dries fresh chicken manure with a moisture content of 65%

WHY SHOULD AN ORGANIC FERTILIZER DRYER CHOOSE A SUITABLE HEAT SOURCE

When choosing an organic fertilizer dryer, it is necessary to choose a suitable heat source, and choosing a reasonable heat source can effectively save the drying cost of the production line. We usually see a lot of heat sources that can maintain the normal operation of the dryer. Generally, the heat sources generated by electric heating and coal combustion are more used. Currently, gas is more used in production lines. 1 First of all, the safety of the organic fertilizer dryer on the organic fertilizer production line must be considered. During the processing of the organic fertilizer production line, there will be some dust inside, as well as some organic

INTRODUCTION OF ORGANIC FERTILIZER PRODUCTION LINE

1. Pulverizing equipment (new semi-wet material pulverizer – vertical pulverizer and horizontal pulverizer, the internal structure has chain type and hammer type) 2. Mixing equipment (mixing mixers – including vertical mixers, horizontal mixers, double-shaft mixers, drum mixers, etc.) 3. Conveying equipment (belt conveyor – mobile belt conveyor, stationary belt conveyor, etc.) 4. Granulation equipment (special granulator for organic fertilizers – including disc granulator, new wet granulator, rounder, drum granulator, etc.) 5. Drying and cooling equipment (rotary dryer – also known as tumble dryer, biological organic fertilizer dryer) 6. Screening equipment (screening machine – including drum type and vibration type, etc.) 7. Coating equipment (particle coating machine – the shape of

EXTRUSION GRANULATOR REALIZES GRANULATION OF VARIOUS MATERIALS

The drying-free compound fertilizer production line adopts the drying-free compound fertilizer extrusion granulation process: the solid material is agglomerated by increasing the pressure. Extrusion granulation is actually used for the production of crystalline products, powders, and organic raw materials, and is most suitable for heat-sensitive materials. Applicable materials are: 1. Fertilizers: potassium sulfate, ammonium bicarbonate, potassium chloride, urea, Russian red potassium, NPK compound fertilizer, ammonium chloride, potassium nitrate, monoammonium phosphate, diammonium phosphate, ammonium sulfate, ammonium bicarbonate, magnetic fertilizer, etc. ; 2. Powder materials: ferric oxalate, melamine cyanurate, antioxidants, bromochlorohydantoin, sodium chloride, sodium dichloroisocyanurate, sodium trichloroisocyanurate, cyanuric acid, bleaching powder, zinc oxide , lead oxide, potassium carbonate, strontium carbonate, calcium chloride, calcium hydrogen

EQUIPMENT MAINTENANCE AND REPAIR PRECAUTIONS

1 Daily maintenance safety precautions 1.1 In daily maintenance, you must wear complete labor protection, and it is strictly forbidden to touch the rotating parts with your hands. 1.2 During the daily inspection process, it is necessary to touch the vibration part of the inspection, measure the temperature with a thermometer, and keep away from the rotating part to prevent burns or mechanical damage. 1.3 If any abnormal situation is found in the routine maintenance process, it must be shut down to deal with it, and must not be dealt with when it is turned on to prevent mechanical injury or electric leakage injury. 2 Maintenance safety precautions 2.1 All

ROTARY DRUM GRANULATOR COMMISSIONING AND ACCEPTANCE PROCEDURES

Preparation before test drive (1)The equipment parts are complete, the bolts are fastened, and the test conditions are met. (2)Check whether the clearance between the belt and the roller is appropriate: (3)Instruments and interlocking devices are complete, accurate, sensitive and reliable. (4) Check whether the rotation direction of the motor is correct, and the trial operation of auxiliary machines and supporting equipment is completed. (5)Check that each lubricating part is filled with lubricating oil (grease) as required. (6)Whether there are debris in the cylinder. (7)Before the test run of the whole machine, a single machine test run must be carried out, among which the electric motor is run for 2 hours

WHY CHOOSE DOUBLE SHAFT CHAIN CRUSHER

The double shaft chain crusher is a professional crushing equipment for the crushing of large-volume raw materials. It is widely used in chemical, building materials, mining and other industries. High-strength wear-resistant carbide chain plates with synchronous speed are used in the crushing process, and the crushed materials are uniform and sufficient. At the same time, the material is not easy to stick, and the equipment is easy to clean. Features: 1. The design is reasonable, the working principle of the hammer mill is scientifically used, and the linear speed of the crusher is improved. 2. The design changes the movement line of the material in the crushing chamber, makes full

WHAT ARE THE TYPES OF ORGANIC FERTILIZER CRUSHERS

Our company’s main products are 1-20 tons of organic fertilizer, bio-organic fertilizer, compound fertilizer, compound fertilizer production line, BB fertilizer complete equipment, drying and fermentation equipment for high-humidity materials such as chicken manure. It has created a precedent for the harmless treatment of organic wastes for organic and inorganic biological fertilizer plants, garbage and sewage treatment plants. Today I will introduce several organic fertilizer crushers to you: 1.High Moisture Fertilizer Crusher is mainly for materials with high moisture content and has a wide range of applications; 2.Double Shaft Chain Fertilizer Crusher:mainly for the crushing of bulk materials, and can play a certain mixing role in the production line; 3.Vertical Fertilizer Chain Crusher:

HOW DOES THE SCREENING MACHINE PERFORM THE SCREENING OPERATION

The organic fertilizer screening machine is a commonly used equipment in the production of organic fertilizer and compound fertilizer. It is mainly used for the separation of finished products and returned materials. Screening machine operation process: The roller device is installed obliquely on the frame, and the motor is connected with the roller device through a coupling, and drives the roller device to rotate around its axis. When the material enters the drum device, due to the inclination and rotation of the drum device, the material on the screen surface is turned over and rolled, so that the qualified material (under-screen product) is discharged through the outer screen of the

THE ROLE OF HYDRAULIC LIFT COMPOST TURNER

The hydraulic lift compost turner is used for the fermentation and turning of organic wastes such as livestock and poultry manure, sludge waste, sugar mill filter mud, slag cake and straw sawdust. The role of the hydraulic lift compost turner: 1. Stirring function in raw material conditioning. In fertilizer production, in order to make the raw materials have a reasonable carbon-nitrogen ratio, pH, water content, etc., some auxiliary materials need to be added. The main raw materials and various auxiliary materials, which are roughly stacked together in proportion, can be mixed evenly by the turning machine to achieve the purpose of conditioning. 2. Adjust the temperature of the raw material pile.

NEW TYPE FERTILIZER GRANULATOR–––STIRRING TOOTH GRANULATOR

The stirring tooth granulator developed and produced by EMCC breaks through the conventional organic granulation technology and is suitable for organic fertilizer granulation. The granulation equipment greatly reduces the manufacturing cost. The new type of tooth stirring granulator is in short supply in the domestic and foreign markets, and the energy saving and environmental protection are favored by the majority of users.

HOW TO JUDGE WHETHER THE ORGANIC FERTILIZER PACKAGING MACHINE IS REASONABLE

For a long time, the abuse of chemical fertilizers has led to the decline of the quality of agricultural products. With the improvement of people’s living standards, new requirements have been put forward for the quality of food, and “pollution-free” has become the standard for measuring the quality of vegetables. The development of organic fertilizers and the protection of the ecological environment have become an inevitable trend in fertilizer production. As a common equipment in the modern packaging industry, the organic fertilizer packaging machine has many manufacturers and uneven prices. So, how to judge whether the organic fertilizer packaging machines are reasonable? Professional technicians from Shanghai Exceed Industry Co., Ltd. analyzed the

WHAT ARE THE CHARACTERISTICS OF BB FERTILIZER EQUIPMENT?

BB fertilizer is one of the most demanded types of agricultural fertilizers, and it is also one of the main fertilizers produced by fertilizer manufacturers. Our company absorbs domestic and foreign advanced technology to manufacture the BB fertilizer production line, which is of high quality and low price, and is a good helper for your production activities. let’s see. Highlights of BB fertilizer equipment production line: 1. The batching scale adopts the static batching method, the batching is accurate, and the quantity of ingredients can be up to 5-10 tons per hour; 2.Due to the poor fluidity of the raw materials, a large inclination belt conveyor is used for feeding,

COMPOST TURNER MAINTENANCE AND MAINTENANCE TIPS

The organic fertilizer composter is a special fermentation equipment for producing bio-organic fertilizer. Compost Turner Maintenance and Maintenance Tips: (1) Daily maintenance and inspection (after working for 4 hours), check whether the connecting bolts, nuts and plugs are loose. (2) Check the pins of all parts, whether the cotter pins are damaged or not, and replace them if necessary (the cotter pins must not be replaced by other materials), (3) Check whether the rotary knife on the drum is damaged and whether the fastening bolts are loose, make up and tighten if necessary. (4) Clean the hardened attachments on the turner. (5) After 90 days of operation of the turner,

ORGANIC FERTILIZER EQUIPMENT TURNS PIG MANURE INTO TREASURE

In recent years, with the continuous deepening of the concept of environmental protection, the traditional breeding mode has the problems of “scattering, chaos and pollution”, which can no longer meet the development requirements of the breeding industry of the times. In order to adapt to th development of the times, many environmental protection facilities have appeared, such as fermentation turner,mixing mixer, organic fertilizer granulator,etc., which can effectively solve the environmental pollution caused by organic wastes in livestock and poultry breeding industries, reduce the eutrophication of surface water caused by pollution, and help improve the safety and quality of agricultural products. It has laid a good foundation for human beings to

ADVANTAGES OF BB FERTILIZER EQUIPMENT

In the production process of BB fertilizer equipment, various products can be produced by adjusting the ingredients and proportions of the formula, so BB fertilizer has become the best choice for balanced fertilization. How to give full play to the maximum efficiency of BB fertilizer machinery and produce high-quality BB fertilizer products in order to achieve market recognition, we need to pay attention to the problems in the following aspects. 1. Comprehensive nutrients and high content: BB fertilizer is mainly based on nitrogen, phosphorus and potassium. The three elements mainly come from urea, ammonium phosphate and potassium chloride, and then moderate and trace elements are added according to the needs of

EQUIPMENT COMPOSITION OF A COMPLETE EXTRUSION GRANULATION PRODUCTION LINE

The complete organic fertilizer extrusion granulation production line consists of hopper and feeder, roller extrusion granulator, dryer, rotary screen, bucket elevator, belt conveyor, packaging machine and scrubber, etc. The equipment above is just a recommendation, we can also customize the production line for you according to your needs. Welcome to inquire.

WHAT TYPES OF ORGANIC FERTILIZER COMPOST TURNERS ARE THERE

The compost turner is divided into two types: the compost turner that can walk on the ground and the trough compost turner that works on the fermentation tank.